Industrial Lifting Equipment: What Is All the Fuss About?

With all the heavy loads that need to be lifted and moved, using industrial lifting equipment is a must in almost all factories, construction sites, warehouses, and docks, since these heavy-duty tools will save time and energy, make things easier for the workers, and ensure their safety on the job site.

According to the data provided by Data Bridge Market Research, the global industrial lifting equipment market is projected to reach USD 107.72 billion by the year 2029. So, adding them to any tool shop collection would be a lucrative business plan.

This is great news for lifting equipment importers, distributors, and retailers. The first step towards a successful investment in this field is to choose a reliable brand among the various lifting equipment suppliers that compete in the crowded market. The best suppliers are the ones that offer a wide variety of the best quality tools, engineered to last long and designed to endure the heaviest of loads.

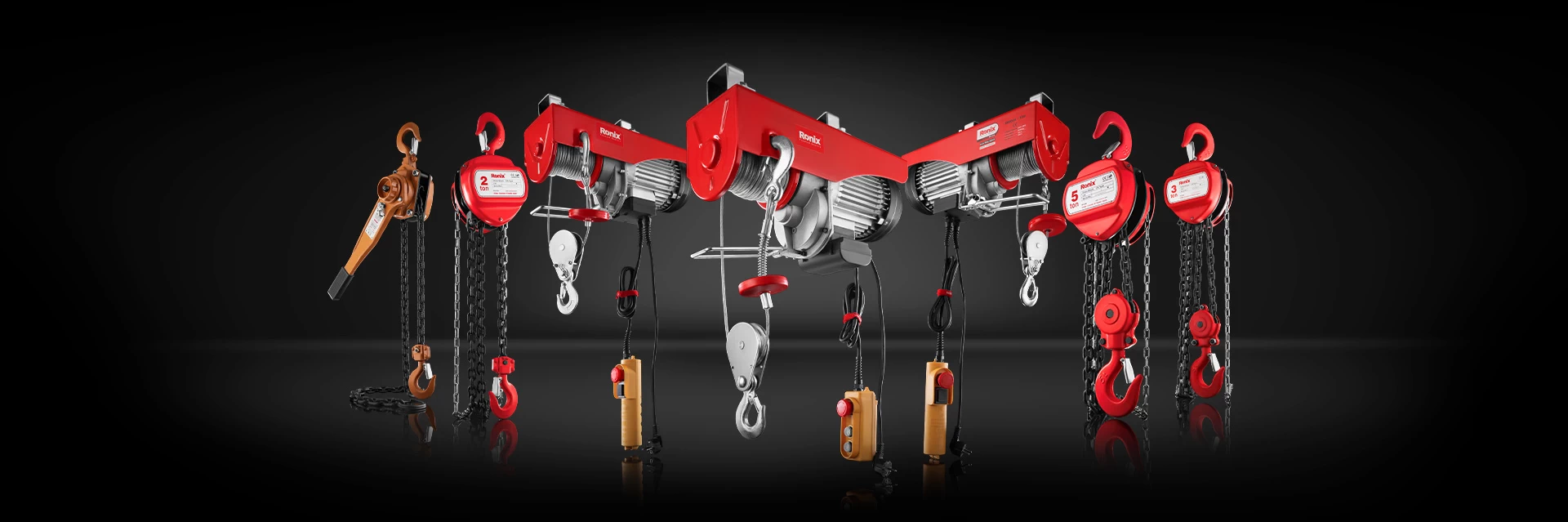

How many types of Lifting equipment are there?

These tools vary in mechanism, capacity, material, etc. There are various lifting tools names in the market applicable across multiple job sites. Let us talk about some of them:

Electric Hoists: Ideal for any job site, electric hoists are a kind of power tool used for raising and lowering loads (vertically). Depending on their capacity, these tools can lift loads up to 10,000kg and are suitable for giant construction sites and large-scale industries.

Chain Blocks: Chain blocks are hand-operated tools that can easily hoist and lower massive loads weighing up to 50,000 kg. They’re considered some of the safest tools on the market. Their safety rates are four times higher than their capability, and this feature makes them a reliable tool.

Lever Hoists: Lever hoists are manual lifters that can raise, lower, or draw loads up to 10,000 kg but have a smaller capacity than chain blocks. Another distinction is that chain blocks raise and lower large objects vertically, but lever hoists pull and hoist in multiple directions.

Wire Rope Hoists: Wire rope hoists are available in the market in manual and electric types, although manual ones are more common. Wire rope hoists can move the loads upwards, downwards, and in different directions.