Menu

Categories

Product Category

Angle Grinders

Electric Screwdrivers

Rotary Hammers

Demolition Hammers

Polishers

Wood Router & Trimmer

Electric Massage guns

Electric Planers

Air Blower

Paint Sprayer

air compressor

Welding Machine

Socket Fusion Welder

Soldering Irons

Heat Gun

Glue Gun

Chainsaw

Grass Cutters

Pressure Washers

Industrial Vacuum Cleaners

Portable Generators

Power Tool Batteries & Chargers

Electric Impact Wrench

Electric Ratchet Wrench

Oscillating Tools

Paddle Mixer

Electric Pruning Shears

Concrete Vibrators

Forced Air Heaters

Earth Augers

Sheep Shears

Pet Grooming Kit

Tile Vibration Machine

Industrial Fan

Product Category

Pliers

Screwdrivers

Hammers

axe

Clamps

Caulking Gun

Grease Gun

Hand Scraper

staple Gun

Sprayer

Hand Saws

Chisels

Steering Wheel Lock

Foot Pump

Pipe Fitting Tools

Door Closer

Hand Tool Sets

Test Pen

Hose Reels

Rotary Hand Pump

Hand Truck

Hand Trowels

Grease Pumps

Vacuum Suction Cups

Shovels

Spring Compressors

Grabbing & Pick Up Tools

Hand Files

Others

Product Category

Flashlight

Spotlight

Headlamp

Cordless lights

LED Neck Light

Camping Lanterns & Lights

Product Category

Tape Measures

laser Distance Meter

Spirit Levels

Laser Levels

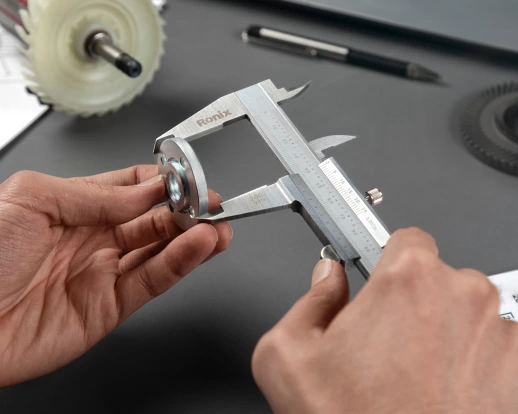

Calipers

Measuring Square

Micrometers

Digital Scales

Measuring Wheels

Feeler Gauges

Product Category

Work Gloves

Safety Glasses

Safety Helmet

Safety Clothing

Welding Helmets

Product Category

Air Tools Accessories

Socket accessories

Drill Extensions

Welding Accessories

Abrasive Accessories

Concrete Vibrator Shaft

Pump Accessories

Laser Level Accessories

Product Category

Electric Hoist

Chain Block

Lever Hoist

Pallet Jacks

Product Category

Bottle Jack

Floor Jack

Jack Stand

Engine Hoist

Transmission Jack

Ratchet Jacks

Engine Stand

CORDLESS

Cordless

Cordless Tools Cordless Drills Cordless Angle Grinders Cordless Rotary Hammers Cordless Saws Cordless Polishers Cordless Sanders Cordless Paint Sprayers Cordless Chainsaws Cordless Blowers Cordless Hedge Trimmer Cordless Brush Cutters Cordless Pressure Washers Cordless Vacuum Cleaners Cordless Massage GunMenu

No outlets in sight? No problem!

The collection of Ronix cordless tools allows for working in any job site even if there isn’t any direct connection to an electrical outlet.

But what’s more, is the possibility to use one battery on a wide range of tools so there will be no need to pay for several batteries. Explore our collection and you will find what you need!

Menu

Drills are an inseparable part of workshops and toolboxes. But we want to separate them from the outlet and have them be by the user wherever they need. The collection of Ronix cordless drills comes in a wide range, meaning there’s an answer for anyone. Go through the list and categories to find what’s best for you.

Menu

Want the grind but not the hold-back?

The freedom of cutting, grinding, deburring, finishing, and polishing without being bound by a cord. From bench grinders to die grinders to wall chasers to mini ones, you can find what works best in the Ronix collection of cordless angle grinders.

Menu

Being heavy-duty doesn’t mean you can’t go boundless. Don’t let the large tool fool you!

You can find in the Ronix collection a variation of cordless rotary hammers, tailored to answer any demand. They are as powerful as they can be, and won’t keep the user restricted in one place.

Menu

Talk about variety!

The Ronix collection offers cordless saws in different shapes, forms, and functions for various applications. Whether it’s woodworking, construction, DIY projects, or any other task where cutting something in the blink of an eye is of issue, a power saw will save the day. But imagine it being cordless which offers maximum convenience and ease of use.

Menu

Move around that car and polish those scratched spots with no limits is possible with the Ronix collection of cordless polishers. Benefiting from the mobility and ease of use in a cordless polisher, car enthusiasts, professionals, and DIYers will definitely enjoy this convenient tool. Useable on car paint, metal, and other materials that need finishing touches. Just scroll through the wide range of this tool and have your pick!

Menu

A smoothing session lead smoothly!

Woodworking, home projects, and DIY activities can all benefit from this tool. And what is that makes everything better?! Having no cords.

The Ronix collection of cordless sanders are what will make any workshop complete and won’t have any hands strained for sanding manually.

Menu

What’s the best tool for painting or staining project outdoors?

In sites where access to a power outlet is limited, the only thing that can come to the rescue is a cordless paint sprayer. Imagine the satisfying feeling of covering a surface with paint spray alongside the convenience of not being bounded by a cord. That’s what the Ronix cordless paint sprayers provide.

Menu

It’s needless to a power outlet but powerful enough to get the job done and more!

The Ronix cordless chainsaws are best for cutting wood, pruning trees, and other outdoor cutting tasks without needing to be connected to a power outlet. Just a charged-up lithium-ion battery on the tool will get the job done.

Menu

You want a blower but you will be blown away by the selection of the cordless ones we carry.

Of course, you need your blower outside. So why bother with a generator to provide you with the power? Just choose a cordless one from our menu and serve yourself!

Menu

Achieving perfect edges on the hedges requires a professional hedge trimmer and what’s better than one that’s cordless? Outdoors being the main setting of this tool, working without the need to be connected to an outlet is a huge bonus and even a must. Ronix offers these tools in a variety of models featuring different options.

Menu

A brush cutter is a must-have when it comes to cutting dense vegetation, thick brush, and small trees. For maintaining large properties, farms, and forested areas, a hand saw might not be enough. Explore through the collection of Ronix brush cutters to find what is the best option you can find.

Menu

The cleaning force; boundless!

The Ronix cordless pressure washers are designed to provide the user with the ultimate cleaning power without the need for a power cord or a constant water supply. They are best for when portability is a priority and convenience matters. So, dive into the world of Ronix's collection of cordless pressure washers.

Menu

To clean floors, carpets, upholstery, and other surfaces as such, a cordless vacuum cleaner will come to aid. These specific types of vacuum cleaners offer both the power and the mobility one might need in the clean-up sessions. As they are cordless, they are the best option for quick cleanups and cleaning areas where an electric outlet is not accessible.

Menu

Calling out to all the athletes, fitness enthusiasts, and anyone looking for at-home massage therapy!

The search for relaxation ends here as a massage gun is all a tired, painful muscle needs. And also, their being cordless makes everything much better as they can be taken anywhere. Look through the Ronix collection of massage guns for the ultimate convenience.

Professional

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Wholesale Hacksaw Blade

Saw Blade

Hacksaw Blade

- 16

- 32

- 64

Sort By

- New Items

- Best Sellers

- Most Viewed

Are you up to a successful investment in tools and equipment?

Need To Power Up Your Business with a Smart Investment?

Need To Power Up Your Business with a Smart Investment?

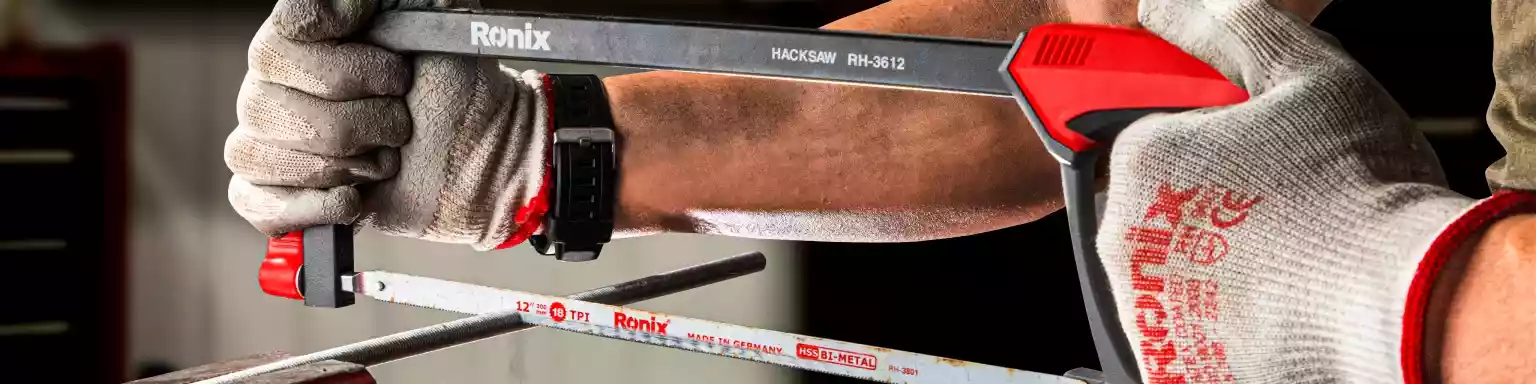

Hacksaw blades; an economical option for cutting tough materials

Scroll Down For more Information

The design of hacksaw blades is to help the user achieve a smoother and more accurate cutting experience, which is why it is important to choose the most appropriate blade for the job. It is the user’s responsibility to know how to choose the equipment that will be beneficial to them for a specific task.

Different hacksaw blades

In general, these items cost a modest amount, but the blade you choose depends on the type of material your customers want to cut and the type of tool they have (manual or power type). This will also have a significant impact on the final price. But what are the differences between manual and power hacksaw blades?Blades used in a manual hacksaw have finer tooth pitches which help with a smooth and precise cut. Whereas in power hacksaw blades the tooth pitch is rougher and is better for cutting larger and thicker materials. Also, the tooth shapes in a manual hacksaw blade have a specific angle to make cutting through metals and plastics easier with the force of the hand. On the other hand, power hacksaw blades have a certain geometry that is designed for high-speed cutting without wearing out.

- Hacksaw blades can be supplied in various materials

Tungsten: These hacksaw blade types are typically for wood, metal, copper, aluminum, and PVC.

Carbide: The carbide is ideal for steel, stainless steel, aluminum, copper, and zinc.

Diamond: These are suitable to cut stone, tile, marble, and ceramic.

Bimetal or HSS: They are a wonderful option for light metal.

- The spacing of the teeth

- The length of the saw blade teeth

- The number of teeth on the blade

- The shape of the teeth of the blade

Discover the sharpest hacksaw blade available on the market

Customers have several considerations when purchasing a hacksaw blade; among them, the power, material, and strength of the tool are the most important factors. Ronix, as a premier manufacturer and supplier of hacksaw blades, is committed to providing customers with reliable, powerful, and heavy-duty tools that make quick and easy cuts. Here are some of the most important facts about these handy tools:

- Rugged steel body for flexibility, safety, and durability.

- High-speed steel teeth to reduce friction and improve cutting performance.

- Resistant to breakage and long life, ideal for steel, aluminum, plastic, and other hard materials.

- Vacuum heat treatment to create harder edges for faster and easier cutting.

Why Ronix?

Ronix is a trusted brand that helps tool importers and distributors purchase high-quality items at reasonable prices.

Our products are developed by a leading R&D team in Germany. We also manage all the production and delivery phases and steps by following five core values: product quality, affordability, product variety, professional behavior, and after-sales service.

Certainly, the Ronix team guarantees total customer satisfaction by offering its beneficial wholesale hacksaw blades.

China’s showroom

Dubai’s showroom

Germany’s showroom

FAQ

Yes, for small quantities, such as samples we can offer you Express delivery and send your orders by air planes.

Ronix Hacksaw blades are made of highly resistant materials such as HSS Bi-metal.

After your order is registered it takes only 15 days for Ronix to prepare it for loading and shippment.

Do you want to invest in the Hacksaw blades business?

Your message was successfully received

Ronix Offices