All About Electric Saws

Menu

Categories

Product Category

Angle Grinders

Electric Screwdrivers

Rotary Hammers

Demolition Hammers

Polishers

Wood Router & Trimmer

Electric Massage guns

Electric Planers

Air Blower

Paint Sprayer

air compressor

Welding Machine

Socket Fusion Welder

Soldering Irons

Heat Gun

Glue Gun

Chainsaw

Grass Cutters

Pressure Washers

Industrial Vacuum Cleaners

Portable Generators

Power Tool Batteries & Chargers

Electric Impact Wrench

Electric Ratchet Wrench

Oscillating Tools

Paddle Mixer

Electric Pruning Shears

Concrete Vibrators

Forced Air Heaters

Earth Augers

Sheep Shears

Pet Grooming Kit

Tile Vibration Machine

Industrial Fan

Hot knife foam cutters

Product Category

Pliers

Screwdrivers

Hammers

axe

Clamps

Caulking Gun

Grease Gun

Hand Scraper

staple Gun

Sprayer

Hand Saws

Chisels

Steering Wheel Lock

Foot Pump

Pipe Fitting Tools

Door Closer

Hand Tool Sets

Hose Reels

Hand Truck

Hand Trowels

Grease Pumps

Vacuum Suction Cups

Shovels

Spring Compressors

Grabbing & Pick Up Tools

Hand Files

Others

Hand Pumps

Voltage Testers

Paint Rollers

Ladders

Garden Rakes

Hand Cultivators

Drywall Tools

Product Category

Flashlight

Spotlight

Headlamp

Cordless lights

LED Neck Light

Camping Lanterns & Lights

Product Category

Tape Measures

laser Distance Meter

Spirit Levels

Laser Levels

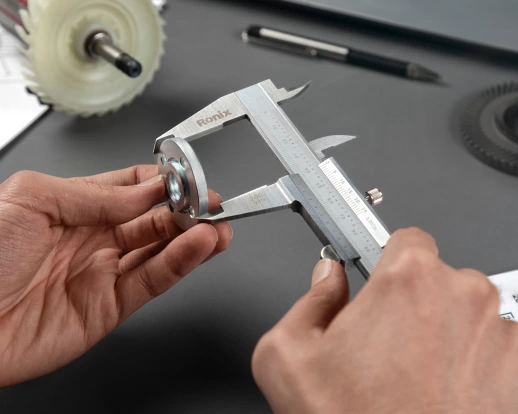

Calipers

Measuring Square

Micrometers

Digital Scales

Measuring Wheels

Feeler Gauges

Multimeters

Sound Level Meter

Anemometers

Digital Protractor

Wooden folding ruler

Product Category

Work Gloves

Safety Glasses

Safety Helmet

Safety Clothing

Welding Helmets

Product Category

Air Tools Accessories

Socket accessories

Drill Extensions

Welding Accessories

Abrasive Accessories

Concrete Vibrator Shaft

Pump Accessories

Planer blades

Laser Level Accessories

Product Category

Electric Hoist

Chain Block

Lever Hoist

Pallet Jacks

Product Category

Bottle Jack

Floor Jack

Jack Stand

Engine Hoist

Transmission Jack

Ratchet Jacks

Engine Stand

CORDLESS

Cordless

Cordless Tools Cordless Drills Cordless Angle Grinders Cordless Rotary Hammers Cordless Saws Cordless Polishers Cordless Sanders Cordless Paint Sprayers Cordless Chainsaws Cordless Blowers Cordless Hedge Trimmer Cordless Brush Cutters Cordless Pressure Washers Cordless Vacuum Cleaners Cordless Massage GunMenu

No outlets in sight? No problem!

The collection of Ronix cordless tools allows for working in any job site even if there isn’t any direct connection to an electrical outlet.

But what’s more, is the possibility to use one battery on a wide range of tools so there will be no need to pay for several batteries. Explore our collection and you will find what you need!

Menu

Drills are an inseparable part of workshops and toolboxes. But we want to separate them from the outlet and have them be by the user wherever they need. The collection of Ronix cordless drills comes in a wide range, meaning there’s an answer for anyone. Go through the list and categories to find what’s best for you.

Menu

Want the grind but not the hold-back?

The freedom of cutting, grinding, deburring, finishing, and polishing without being bound by a cord. From bench grinders to die grinders to wall chasers to mini ones, you can find what works best in the Ronix collection of cordless angle grinders.

Menu

Being heavy-duty doesn’t mean you can’t go boundless. Don’t let the large tool fool you!

You can find in the Ronix collection a variation of cordless rotary hammers, tailored to answer any demand. They are as powerful as they can be, and won’t keep the user restricted in one place.

Menu

Talk about variety!

The Ronix collection offers cordless saws in different shapes, forms, and functions for various applications. Whether it’s woodworking, construction, DIY projects, or any other task where cutting something in the blink of an eye is of issue, a power saw will save the day. But imagine it being cordless which offers maximum convenience and ease of use.

Menu

Move around that car and polish those scratched spots with no limits is possible with the Ronix collection of cordless polishers. Benefiting from the mobility and ease of use in a cordless polisher, car enthusiasts, professionals, and DIYers will definitely enjoy this convenient tool. Useable on car paint, metal, and other materials that need finishing touches. Just scroll through the wide range of this tool and have your pick!

Menu

A smoothing session lead smoothly!

Woodworking, home projects, and DIY activities can all benefit from this tool. And what is that makes everything better?! Having no cords.

The Ronix collection of cordless sanders are what will make any workshop complete and won’t have any hands strained for sanding manually.

Menu

What’s the best tool for painting or staining project outdoors?

In sites where access to a power outlet is limited, the only thing that can come to the rescue is a cordless paint sprayer. Imagine the satisfying feeling of covering a surface with paint spray alongside the convenience of not being bounded by a cord. That’s what the Ronix cordless paint sprayers provide.

Menu

It’s needless to a power outlet but powerful enough to get the job done and more!

The Ronix cordless chainsaws are best for cutting wood, pruning trees, and other outdoor cutting tasks without needing to be connected to a power outlet. Just a charged-up lithium-ion battery on the tool will get the job done.

Menu

You want a blower but you will be blown away by the selection of the cordless ones we carry.

Of course, you need your blower outside. So why bother with a generator to provide you with the power? Just choose a cordless one from our menu and serve yourself!

Menu

Achieving perfect edges on the hedges requires a professional hedge trimmer and what’s better than one that’s cordless? Outdoors being the main setting of this tool, working without the need to be connected to an outlet is a huge bonus and even a must. Ronix offers these tools in a variety of models featuring different options.

Menu

A brush cutter is a must-have when it comes to cutting dense vegetation, thick brush, and small trees. For maintaining large properties, farms, and forested areas, a hand saw might not be enough. Explore through the collection of Ronix brush cutters to find what is the best option you can find.

Menu

The cleaning force; boundless!

The Ronix cordless pressure washers are designed to provide the user with the ultimate cleaning power without the need for a power cord or a constant water supply. They are best for when portability is a priority and convenience matters. So, dive into the world of Ronix's collection of cordless pressure washers.

Menu

To clean floors, carpets, upholstery, and other surfaces as such, a cordless vacuum cleaner will come to aid. These specific types of vacuum cleaners offer both the power and the mobility one might need in the clean-up sessions. As they are cordless, they are the best option for quick cleanups and cleaning areas where an electric outlet is not accessible.

Menu

Calling out to all the athletes, fitness enthusiasts, and anyone looking for at-home massage therapy!

The search for relaxation ends here as a massage gun is all a tired, painful muscle needs. And also, their being cordless makes everything much better as they can be taken anywhere. Look through the Ronix collection of massage guns for the ultimate convenience.

Professional

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Wholesale Electric Saws

- Drills

- Pneumatic Tools

- Angle Grinders

- Electric Screwdrivers

- Electric Saws

- Sanders

- Polishers

- Wood Router & Trimmer

- Electric Planers

- Air Blower

- Paint Sprayer

- Rotary Hammers

- Demolition Hammers

- air compressor

- Welding Machine

- Socket Fusion Welder

- Soldering Irons

- Heat Gun

- Glue Gun

- Chainsaw

- Nail Gun

- Grass Cutters

- Pressure Washers

- Industrial Vacuum Cleaners

- Portable Generators

- Power Tool Batteries & Chargers

- Electric Impact Wrench

- Water Pump

- Paddle Mixer

- Oscillating Tools

- Electric Pruning Shears

- Concrete Vibrators

- Forced Air Heaters

- Sheep Shears

- Electric Massage guns

- Electric Ratchet Wrench

- Pet Grooming Kit

- Earth Augers

- Tile Vibration Machine

- Industrial Fan

- Hot knife foam cutters

- 16

- 32

- 64

Sort By

- New Items

- Best Sellers

- Most Viewed

Are you up to a successful investment in tools and equipment?

Need To Power Up Your Business with a Smart Investment?

Need To Power Up Your Business with a Smart Investment?

Electric Saws; Cutting-Edge Changes in Your Business

Scroll Down For more Information

All about Electric Saws

Woodworking has always been a primary industry all over the world. It applies to different fields of work, specifically architecture, construction, furniture, and arts. power saws are among the essential tools that have developed the industry over time.Considering the leading role, it is an excellent opportunity for tool distributors, importers, and shop owners to connect strongly with this field by providing Wholesale Electric Saws.

Power Saws can cut across different materials, such as wood, metal, and plastic, and are offered in a wide range of types.

In addition, they are presented in either Corded or Cordless with Brushed or Brushless motors.

Different Types of Electric Saw

Electric Saws include various cutting tools, which come in handy in different situations and fields. Here are some of the types:Miter saw: It is a high-power woodworking machine to make precise cross-cuts and miters. However, it is capable of cutting straight too. It is usually categorized into three: Sliding, Compound, and Sliding Compound.

Chop Saw: Also called Cut-Off Saw is typically used to cut dense materials such as metal, ceramic, and concrete with an abrasive disc.

Circular saw: A Circular saw there is another type of power saw which cuts through many materials such as wood, masonry, and plastic. It can operate as a portable tool or be set up on a machine.

Jigsaw: Jigsaws are handheld electric saws with a short blade that moves up and down at a set speed. They make straight lines, but their ability to create curved and irregular lines makes them more useful.

The cutting part is narrow and not intended for heavy work, but it can be cut through various materials such as wood, metal, plastic, and ceramic tile.

Reciprocating saw: A reciprocating saw, like a jigsaw, has a blade that travels back and forth swiftly. They cut through many materials, such as wood, tubing, and plastic—metal, including pipes and nails, and are also used in demolition projects.

Table saw: It is a powerful, freestanding tool. It has a circular disc that extends below the table’s surface; users can push the material up to the edge, and it will cut right through without having to lower the blade. They make straight and angled ones, increasing their versatility. They are frequently used to chop boards to size efficiently.

Chain saws: They are power saws for cutting trees and can be used to trim and shape hedges. For wood carving, some artisans even utilize them. Along with electric chainsaws, gasoline-powered chainsaws are available on the market.

What Do Pro-Users Look for?

There are countless power saw types, and you can add many of them to the list above. Each of these tools is applicable in a particular situation, so they must have some unique qualities to meet the standards. But there are some points that partially all are to own to respond to the professional users effectively.

Here you can see some of them:

Speed Adjustment: One of their essential features is the speed range indicated by the Revolution Per Minute unit. Partly all the saws are to perform at various speeds (wide RPM range) to cut varying materials accurately and as quickly as possible.

Safety Equipment: Working with power saws can deliver so many risks. While working with them, chips, dust, and spark ejection cause eye and face damage. So, they must be equipped with high-quality protection guards to avoid possible danger.

Anti-Dust System: In woodworking, dust causes more trouble than simply damaging people. It messes up the worksite and harms the tool itself. An Anti-Dust System is a great solution to solve the problem correctly. So, an ideal electric cutting machine should have one to work properly.

Ergonomic Design: Power Saws are offered in different shapes. Some are hand-held, and some are mounted on a table or another device. Meanwhile, common among them is that they all should be ergonomically designed to help an easy and convenient operation. Also, rubber handles and work clamps can be applied in most of them to enable more efficient processes.

Cordless Saw: A Trending Cutting Solution

Among the different models of electric saws for sale, cordless ones are the most in demand. A cordless saw does not depend on a power cord to operate, so it allows the user to move around with no limitations or risk of tripping over the wire.

Before the current technological advancements, corded saws were considered to be more powerful and reliable than battery-operated ones but now, with the development of compact cell lithium-ion batteries and brushless motors, the performance, power, efficiency and reliability of the latter group has enhanced significantly. Today, a five-star cordless saw comes with more runtime and higher power output to meet the needs and expectations of any customer and maximize the bang for their buck.

Cordless electric saws for sale might be more expensive than their corded counterparts but they are lighter, more efficient, and safer to use which justifies their growing popularity.

Why Ronix?

Whether you're a Distributor, Wholesaler, or Importer looking for the most versatile, all-purpose wholesale saw that can fulfill your pro customers’ demand, Ronix, as a top tools manufacturer, is the brand you are seeking. We manufacture a wide range of electric saws with the best quality under the supervision of a leading research and development team.

In addition to these specifics, we complete all phases and stages of production and delivery while adhering to 4 central values: product quality, affordable price, product variety, and after-sales service internationally.No doubt the Ronix team assures complete customer pleasure!

Electric circular Saw 4311

Electric miter Saw 5102

Are you up to a successful investment in Electric Saws?

Electric Saw 5403

Electric Saw 8305

Electric Saw 4110

Your message was successfully received

Ronix Offices