All About Electric Drills

Menu

Categories

Product Category

Angle Grinders

Electric Screwdrivers

Rotary Hammers

Demolition Hammers

Polishers

Wood Router & Trimmer

Electric Massage guns

Electric Planers

Air Blower

Paint Sprayer

air compressor

Welding Machine

Socket Fusion Welder

Soldering Irons

Heat Gun

Glue Gun

Chainsaw

Grass Cutters

Pressure Washers

Industrial Vacuum Cleaners

Portable Generators

Power Tool Batteries & Chargers

Electric Impact Wrench

Electric Ratchet Wrench

Oscillating Tools

Paddle Mixer

Electric Pruning Shears

Concrete Vibrators

Forced Air Heaters

Earth Augers

Sheep Shears

Pet Grooming Kit

Tile Vibration Machine

Industrial Fan

Hot knife foam cutters

Product Category

Pliers

Screwdrivers

Hammers

axe

Clamps

Caulking Gun

Grease Gun

Hand Scraper

staple Gun

Sprayer

Hand Saws

Chisels

Steering Wheel Lock

Foot Pump

Pipe Fitting Tools

Door Closer

Hand Tool Sets

Hose Reels

Hand Truck

Hand Trowels

Grease Pumps

Vacuum Suction Cups

Shovels

Spring Compressors

Grabbing & Pick Up Tools

Hand Files

Others

Hand Pumps

Voltage Testers

Paint Rollers

Ladders

Garden Rakes

Hand Cultivators

Drywall Tools

Product Category

Flashlight

Spotlight

Headlamp

Cordless lights

LED Neck Light

Camping Lanterns & Lights

Product Category

Tape Measures

laser Distance Meter

Spirit Levels

Laser Levels

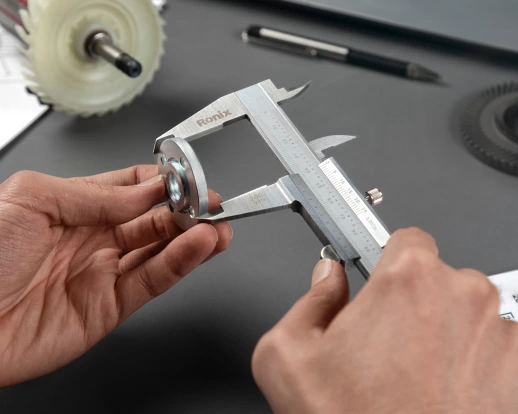

Calipers

Measuring Square

Micrometers

Digital Scales

Measuring Wheels

Feeler Gauges

Multimeters

Sound Level Meter

Anemometers

Digital Protractor

Wooden folding ruler

Product Category

Work Gloves

Safety Glasses

Safety Helmet

Safety Clothing

Welding Helmets

Product Category

Air Tools Accessories

Socket accessories

Drill Extensions

Welding Accessories

Abrasive Accessories

Concrete Vibrator Shaft

Pump Accessories

Planer blades

Laser Level Accessories

Product Category

Electric Hoist

Chain Block

Lever Hoist

Pallet Jacks

Product Category

Bottle Jack

Floor Jack

Jack Stand

Engine Hoist

Transmission Jack

Ratchet Jacks

Engine Stand

CORDLESS

Cordless

Cordless Tools Cordless Drills Cordless Angle Grinders Cordless Rotary Hammers Cordless Saws Cordless Polishers Cordless Sanders Cordless Paint Sprayers Cordless Chainsaws Cordless Blowers Cordless Hedge Trimmer Cordless Brush Cutters Cordless Pressure Washers Cordless Vacuum Cleaners Cordless Massage GunMenu

No outlets in sight? No problem!

The collection of Ronix cordless tools allows for working in any job site even if there isn’t any direct connection to an electrical outlet.

But what’s more, is the possibility to use one battery on a wide range of tools so there will be no need to pay for several batteries. Explore our collection and you will find what you need!

Menu

Drills are an inseparable part of workshops and toolboxes. But we want to separate them from the outlet and have them be by the user wherever they need. The collection of Ronix cordless drills comes in a wide range, meaning there’s an answer for anyone. Go through the list and categories to find what’s best for you.

Menu

Want the grind but not the hold-back?

The freedom of cutting, grinding, deburring, finishing, and polishing without being bound by a cord. From bench grinders to die grinders to wall chasers to mini ones, you can find what works best in the Ronix collection of cordless angle grinders.

Menu

Being heavy-duty doesn’t mean you can’t go boundless. Don’t let the large tool fool you!

You can find in the Ronix collection a variation of cordless rotary hammers, tailored to answer any demand. They are as powerful as they can be, and won’t keep the user restricted in one place.

Menu

Talk about variety!

The Ronix collection offers cordless saws in different shapes, forms, and functions for various applications. Whether it’s woodworking, construction, DIY projects, or any other task where cutting something in the blink of an eye is of issue, a power saw will save the day. But imagine it being cordless which offers maximum convenience and ease of use.

Menu

Move around that car and polish those scratched spots with no limits is possible with the Ronix collection of cordless polishers. Benefiting from the mobility and ease of use in a cordless polisher, car enthusiasts, professionals, and DIYers will definitely enjoy this convenient tool. Useable on car paint, metal, and other materials that need finishing touches. Just scroll through the wide range of this tool and have your pick!

Menu

A smoothing session lead smoothly!

Woodworking, home projects, and DIY activities can all benefit from this tool. And what is that makes everything better?! Having no cords.

The Ronix collection of cordless sanders are what will make any workshop complete and won’t have any hands strained for sanding manually.

Menu

What’s the best tool for painting or staining project outdoors?

In sites where access to a power outlet is limited, the only thing that can come to the rescue is a cordless paint sprayer. Imagine the satisfying feeling of covering a surface with paint spray alongside the convenience of not being bounded by a cord. That’s what the Ronix cordless paint sprayers provide.

Menu

It’s needless to a power outlet but powerful enough to get the job done and more!

The Ronix cordless chainsaws are best for cutting wood, pruning trees, and other outdoor cutting tasks without needing to be connected to a power outlet. Just a charged-up lithium-ion battery on the tool will get the job done.

Menu

You want a blower but you will be blown away by the selection of the cordless ones we carry.

Of course, you need your blower outside. So why bother with a generator to provide you with the power? Just choose a cordless one from our menu and serve yourself!

Menu

Achieving perfect edges on the hedges requires a professional hedge trimmer and what’s better than one that’s cordless? Outdoors being the main setting of this tool, working without the need to be connected to an outlet is a huge bonus and even a must. Ronix offers these tools in a variety of models featuring different options.

Menu

A brush cutter is a must-have when it comes to cutting dense vegetation, thick brush, and small trees. For maintaining large properties, farms, and forested areas, a hand saw might not be enough. Explore through the collection of Ronix brush cutters to find what is the best option you can find.

Menu

The cleaning force; boundless!

The Ronix cordless pressure washers are designed to provide the user with the ultimate cleaning power without the need for a power cord or a constant water supply. They are best for when portability is a priority and convenience matters. So, dive into the world of Ronix's collection of cordless pressure washers.

Menu

To clean floors, carpets, upholstery, and other surfaces as such, a cordless vacuum cleaner will come to aid. These specific types of vacuum cleaners offer both the power and the mobility one might need in the clean-up sessions. As they are cordless, they are the best option for quick cleanups and cleaning areas where an electric outlet is not accessible.

Menu

Calling out to all the athletes, fitness enthusiasts, and anyone looking for at-home massage therapy!

The search for relaxation ends here as a massage gun is all a tired, painful muscle needs. And also, their being cordless makes everything much better as they can be taken anywhere. Look through the Ronix collection of massage guns for the ultimate convenience.

Professional

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Menu

Wholesale Electric Power Drills

- Drills

- Pneumatic Tools

- Angle Grinders

- Electric Screwdrivers

- Electric Saws

- Sanders

- Polishers

- Wood Router & Trimmer

- Electric Planers

- Air Blower

- Paint Sprayer

- Rotary Hammers

- Demolition Hammers

- air compressor

- Welding Machine

- Socket Fusion Welder

- Soldering Irons

- Heat Gun

- Glue Gun

- Chainsaw

- Nail Gun

- Grass Cutters

- Pressure Washers

- Industrial Vacuum Cleaners

- Portable Generators

- Power Tool Batteries & Chargers

- Electric Impact Wrench

- Water Pump

- Paddle Mixer

- Oscillating Tools

- Electric Pruning Shears

- Concrete Vibrators

- Forced Air Heaters

- Sheep Shears

- Electric Massage guns

- Electric Ratchet Wrench

- Pet Grooming Kit

- Earth Augers

- Tile Vibration Machine

- Industrial Fan

- Hot knife foam cutters

- 16

- 32

- 64

Sort By

- New Items

- Best Sellers

- Most Viewed

Are you up to a successful investment in tools and equipment?

Need To Power Up Your Business with a Smart Investment?

Need To Power Up Your Business with a Smart Investment?

Power Drills on Your Shelves: Drill Your Way to the Top

Types of Power Drills: Find Your Perfect Fit

Update your tool shop’s shelves with Ronix corded drills that have surprised users with their power and speed. As must-have tools in construction, decoration, carpentry, and DIY projects, drills are remarkably popular among both casual and professional users.A drill is defined by the power, speed, type, and size of the chuck and its maximum drilling capacity in different materials. Power determines the function of each machine.

The chuck of a drill that determines the maximum size of the bit that can be attached to it, comes in 2 main categories: keyed and keyless. Keyed chucks can’t be tightened or loosened unless with a key while keyless ones can be tightened by hand.

Invest in Electric Drills, Power, and Speed

We've got small corded electric drills that pack a punch. Compact, ergonomic, and powerful with speeds of 2700-3600 RPM, these drills are among the best in the market. Their anti-dust switch and customizable speeds make them stand out. The mini drills are designed for comfort, reducing exhaustion during work, and are ideal for those on the move.

Ronix powerful drills are packed in BMC hard cases that make them easier to ship and transport and encourage the customers to buy. Most clients prefer to get whatever they need to use with a tool, all in one package. Our product comes with some of the needed accessories like bits for wood, steel, and concrete, chuck keys, batteries, fast chargers, and connectors.

Ronix: Your Trusted Electric Power Drill Supplier for Quality

It can be tough to find a good power drill supplier in a market with lots of choices. Nobody wants to end up with losses. That's where Ronix comes in. As a trusted supplier with many happy customers worldwide, Ronix is here to make sure you get the best and highest-quality power drills. Plus, we offer great support even after you make the purchase. So, choose Ronix for a reliable and hassle-free experience in getting top-notch wholesale power drills.

Maximize Profits with Wholesale Electric Drills

Ronix - Your Trusted Source for Power Drill Spare Parts

Simple Payment Options for Wholesale Corded Drills

1. How can payments be made for electric compressors for sale orders?

• Ronix provides convenient and flexible payment options for all. For sample orders, full payment is required upon ordering. In the case of bulk purchases, a 30% initial payment is necessary upfront, with the remaining balance due before shipping. Accepted payment methods include both cash and telegraphic transfer (TT).

2. What are the payment options for wholesale compressors?

• Ronix operates under FOB (Free On Board) terms, applicable at Shanghai or Ningbo ports. For bulk orders, a 30% deposit is required upon proforma invoice approval, and the remaining 70% balance should be settled when the order is ready for shipment. Full payment in advance is required for sample orders. Moreover, under specific circumstances and subject to negotiation, we can consider LC at Sight as a potential payment method for bulk power drill orders.

Why Ronix? The Trusted Choice for Quality and Affordability

Among various electric drill suppliers, it is hard to find a brand that fulfills every expectation, from reasonable prices and high quality to ergonomic design. While famous brands mainly focus on quality at the cost of affordability, less known ones try manufacturing less expensive products that are better suited to the clients who have a modest budget, but sacrifice quality. That’s when Ronix comes to the rescue by filling the gap between excellence and affordability.

Ronix is an international tool brand that offers the finest instruments at a reasonable price. Whether you are a casual user looking for electric drills for sale or a distributor in search of wholesale electric drills, Ronix is a great choice that while providing you with high-quality products, helps you boost your business by offering FREE advertising material. Yes, you heard that right!

Ronix team brands your shop or truck and design showrooms for you professionally and provide you with customized t-shirts, plastic bags, caps and stands to promote your Ronix products.

Trust Ronix and it won’t let you down

Dubai's showroom

Germany's showroom

Are you up to a successful investment in corded Drills?

Electric corded Drill 2107

corded Drill 2106C

Electric corded Drill 2114

Your message was successfully received

Ronix Offices