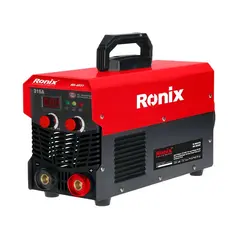

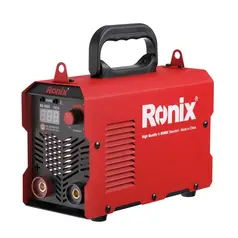

If you’re a welding machine importer you know that buying anything in large numbers can give you worries. Such as:

- How do I know this supplier is reliable?

- Is it safe to trust the delivery timeline and build schedules accordingly?

- How can I find an affordable brand that doesn’t sacrifice quality?

- Will the welding machine supplier have good customer support, warrant, online service, and knowledgeable staff?

Ronix strives to wash all these worries away by giving you great quality alongside a reasonable price on its tools. Also, you will be receiving good customer service provided by our representatives. And as for the delivery, you can rest assured. You can easily buy Wholesale welding machines online and the delivery will be in 15 days.

Meanwhile, we at Ronix have considered the market issue and offered a solution to provide customers with a fair offer.