Taste Success as a Measuring Tool Wholesaler with Ronix

Measuring the length between two points, lines, or objects is one of the first steps of almost any project, a fact that makes different types of distance-measuring tools essential elements in a toolbox. carpenters need measuring equipment to create clean and smooth products and waste less wood in the process, and engineers, architects, or interior designers need them to ensure the precision and safety of the structure they design. To fulfill the needs of such a diverse group of users, you as a measuring tools wholesaler need a supplier that brings a wide variety to the table. Look no further because we’ve got you covered!

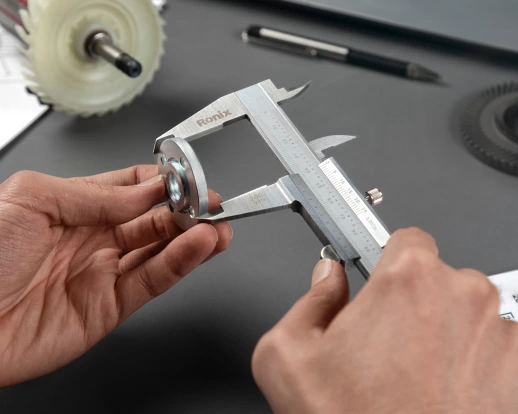

From the basic measurement equipment to the most professional precision measuring tools, Ronix offers all you need to succeed in your target market. Be it self-retracing tape measures, water and dustproof laser distance meter and accurate laser levels or well-built spirit levels, calipers and measuring squares, you can find accurate, durable and versatile items in our collections of wholesale measuring tools, all engineered to deliver reliable results.

But wide variety is not the only feature that makes Ronix stand out in the world of measuring tool suppliers. Scroll down to learn more: