- 8min

- 18130

- 0

Welding is easy but not child’s play, and what makes it possible for everyone to perform is having the right equipment. Among the flood of technical tasks, welding seems and sounds deceptively hard. People are scared of starting it, and they do not know whether they need to be taught, or they can begin by themselves.

If you are a beginner, the first step is to get yourself the necessary welding hand tools. Contrary to what people might think, there are plenty of hand tools used in welding. Apart from welding machines and angle grinders, everything else that welders use is hand tools. In this article, we will give you enough information about all the different types of hand tools that are common hand tools in welding. These hand tools are also used in other fields of metal fabrication. Remember that you may need other hand tools other than the welding hand tools named here in this article depending on your particular application.

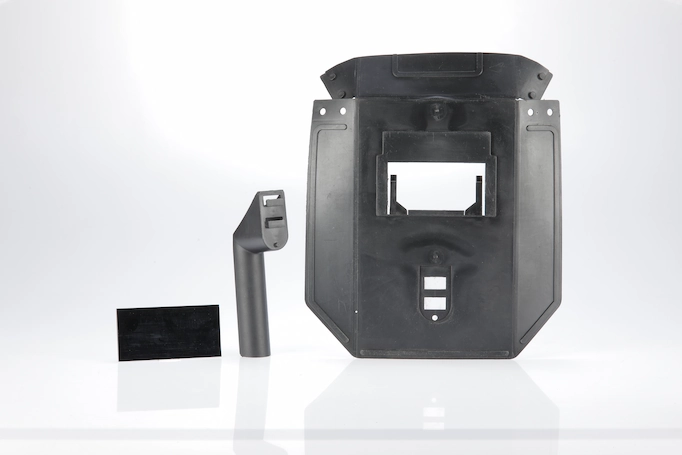

In the latter part of the article, we will be introducing some of the absolute necessities, which can be loosely categorized as hand tools, compromising of basic PPE (Personal Protective Equipment) gear. These equipments include welding gloves, welding helmets (Ronix RH-9015), and welding aprons. You should always keep in mind that in every task, safety comes first, and using the mentioned safety gear can reduce the chance of common welding injuries to the least amount.

Related Article : Use Of Hand Tools

Welding Hand Tools and Their Uses

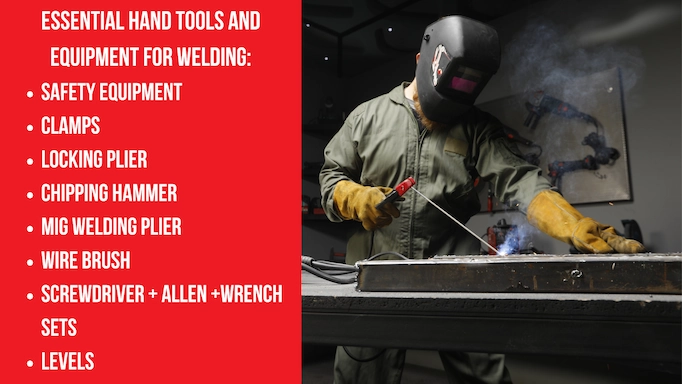

As we mentioned previously in the article, the use of hand tools in welding is as necessary as in any other field. In this part of the article, we will take a glance at the most essential hand tools and their uses in welding. Take note that it is worth investing in buying good welding gear, because the higher the quality of the tools, the higher the quality of the final workpiece. If you are looking for a bare-bones welding hand tools list, look no further.

Clamps

Clamps are one of the most essential welding hand tools. When working in any field of metal fabrication, especially welding, you need clamps to hold the material while working on it. Remember to always have several clamps in your tool kit, even if they are not the best ones in the market. You can never have too many clamps!

One type of clamp that is extremely useful and convenient to use is magnets. They can easily secure your workpiece to do your operations more easily.

ronix, a renowned hand tools supplier, offers premium quality products, ensuring durability, precision, and efficiency for every professional craftsman

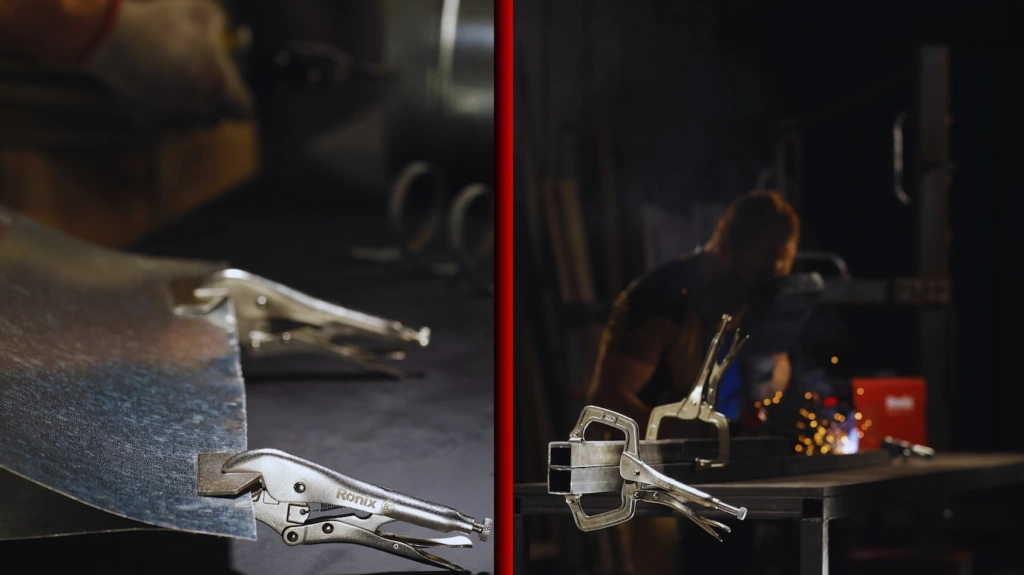

Locking Plier

Locking pliers are extremely useful welding hand tools. These tools can be categorized as a type of clamp, but they are more versatile than clamps in terms of their functionality. There are plenty of different types of locking pliers. Straight-jaw, curved jaw, C-clamp, and sheet metal locking pliers are the most popular variants of these hand tools used in welding.

Chipping Hammer

Chipping hammers are some of the most essential hand tools for welding. They are designed with a pointed pick end on one side and a flat end on the other side. They are used to chip away the slag and bits of metal from your weld in case you need to lay another bead on the same spot or a bead that is going to overlap the first one. Otherwise, it is going to get worked into your puddle and your bead. In addition to that, the flat end of the hammer is used to remove the spatters from alongside welds. The chipping hammer has to be carefully swung and hit the weld to shatter the slag, without causing any damage to the workpiece. Regardless of your welding type (Stick, MIG, TIG), you’re going to use a chipping hammer a ton.

MIG Welding Plier

MIG welding pliers are one othe most essential welder hand tools. Compared to every other plier, MIG pliers provide the users with a broad scope of functionality. As the name explains, they are specially designed to help you with MIG welding. The outer section of the long needle nose allows you to scrape out the splatter and junk from the inside of your cup on your MIG welding gun, and it can also help you to move hot metal safely. The knurled section under the jaws helps you to get the contact tip started to spin and also reinstall it easily.

This plier is also equipped with a wire cutter section to trim your MIG wire at the proper stick out. In case the outer cap on the gun gets tightly jammed when it heats and cools, the big knurled section over the handle helps you to take it off. MIG pliers are going to be the handy small companions of your welding projects.

Related Article : Proper Use of Hand Tools

Wire Brush

Another staple for a clean welding process is a wire brush. The objective of wire brushes is to remove the rust or heat discoloration without damaging the base metal. Wire brushes are categorized under different groups considering their application, such as wire wheel brushes, cup brushes, end brushes, and hand brushes. Wire wheel brushes are used for interpass weld cleaning. All of these functions make wire brushes one of the most important welding hand tools.

Cup brushes are used to prepare large sized areas for the weld. End brushes offer cleaning specifically for hard-to-reach job sites like t-shape ones, and finally, the most common brushes are hand brushes, used for knocking off slags in small welds with few swipes. While purchasing a wire brush, it’s important to consider the size you aim to clean and the roughness of the wires.

Screwdriver Sets, Allen Key Sets, and Wrench Sets

These tools are an essential part of any tool box. Welders often use these tools as they need to fasten and loosen nuts and bolts. To do welding jobs, you need to disassemble and assemble different metal components, whether they are part of structures or vehicles. Therefore, fastening tools such as screwdrivers, allen keys, and wrenches are essential hand tools for welding.

Levels

Before starting the welding process, it is necessary to make sure that the surfaces you are working on are level. Levels are also used in the welding process itself to ensure that the workpiece stays level throughout the operation. This makes levels one of the essential welder hand tools. Welders use spirit levels and laser levels. Laser levels give you more precision.

Other Measuring Equipment

When doing any welding job, you need to measure the angles of your weld and keep your angles consistent. Angle measuring equipment like combination squares and speed squares are indispensable. Also, it goes without saying how essential measuring tapes are, among all the top rated hand tools for welders.

Safety Equipment for Welding

Now that we finished talking about all the other welding hand tools and their uses, it is finally time to talk about probably the most essential equipment for welding which is safety and personal protection equipment. Safety equipment are a necessity for welders as welding is a dangerous task.

Failing to protect your eyes, skin, and lungs could lead to temporary or permenant damages to these body parts. So, if you are looking to start your career in welding, you should look for proper welding clothes and shoes, a welding helmet (preferably an auto-darkening helmet), safety glasses, masks, and respirators.

Other Equipment

We have already talked about welding hand tools for welders as well as proper safety equipment. We need to mention a couple of other stuff before we set you on the way to your welding career path. So, let’s introduce these equipments briefly. A nozzle gel is necessary to maintain the nozzle of your welder. Welding wires and rods are also essential. As a welder, you would also need a fixture table for keeping your workpieces on it and as a surface to do your projects on with more precision.

FAQ

Are hand tools necessary for welders?

Yes, of course. Contrary to what some people might think about wedling, this profession requires more than just welding machines and power tools like angle grinders and drills.

What are some of the hand tools used in welding?

Clamps, locking pliers, MIG welding pliers, chipping hammers, wire brushes, and various measuring tools are some of the most used hand tools by welders.

Arturo

16 November 2020