- 4min

- 6746

- 0

Are you interested in making a DIY epoxy table? The instruction given here is about a creative epoxy resin table with a river and waterfall in the middle, one that’s different from all. This project is not as hard as you think with the tools introduced below.

Click to see this article: How to Make a Wooden Table- Step by Step Guide

Tools Needed

- A Miter Saw

- A Circular Saw

- A Table saw

- A Grinder

- A Welder

Materials Needed

- Hardwood Live Edge Slab

- Square Tube Steel

- Epoxy Resin

- Sealant Tape

- Metallic Pigments

How to Make a DIY Epoxy Resin River Table in 7 Brief Steps

- Prepare the Live Edge Slabs

- Build up an Epoxy Resin Form

- Pour Epoxy Resin in the Built Form

- Build a Metal Table Base

- Clean the Epoxy Resin Slab

- Cut and Join the Waterfall Edge

- Assemble and Finish

Prepare the Live Edge Slabs

- Buy a good quality monolithic wood slab perfect for making a DIY river table.

- Use a string and place it on the center of each end of the slab to find the best cut line.

- Then mark each slab ends for the cut.

- With the help of your circular saw, cut the slab in multiple passes; then, use your jointer to flatten the surfaces of the slabs.

- Machine the slabs down to get slabs with the right thickness, then cut them to the suitable size on your miter saw.

- Clean up the live edges to prepare it for pouring epoxy resin.

- Sand any loose material to make a good surface for the sticking epoxy.

Build up an Epoxy Resin Form

- Make a form for the pouring epoxy.

- Cover the pieces in sealant tape to prevent epoxy resin from sticking.

- Use screws and put the epoxy resin form together; seal the form’s inside corners using more sealant tape.

- Load the live edge slabs into the form.

- Clamp the wood down to keep slabs from floating on the epoxy resin, screw the wood to the form.

- Level the form for pouring the epoxy.

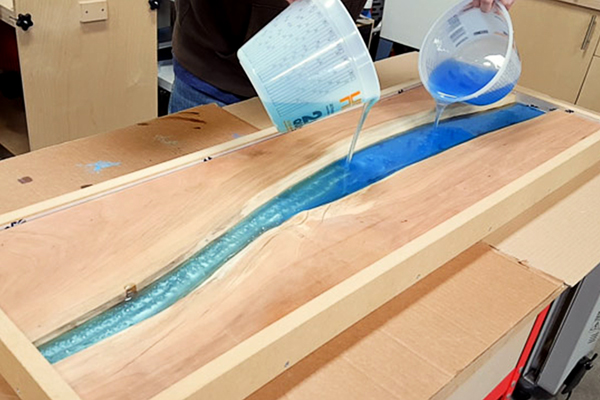

Pour Epoxy Resin in the Built Form

- Measure the gap between slabs and figure out how much epoxy resin you need, here we pour 1-3/4″ epoxy at a time.

- We want a two-color epoxy pour, so we mix epoxy containers, add metallic pigments, and mix them for some minutes.

- Start pouring two epoxy resin bottles from the two ends and let them mix.

Build a Metal Table Base

- Buy some 1” square tube for the table base.

- Use your welder to weld the base together.

- Use your cordless grinder and a flap disc to ground down the welds on the base.

- Drill mounting holes in the base for the top, then spray some matte black paint and matte clear coat on it.

Clean the Epoxy Resin Slab

- After completing the 72 hours cure time, it gets hard.

- Unscrew and remove the sides from the form and remove all screws from the slab bottom.

- Use your planer to remove any excess from the bottom.

- Clean up the sides and square up to one edge on the jointer, then trim the other side on your table saw.

- Go ahead and sand the slab up to 180 grit and take the epoxy up to 400 grit.

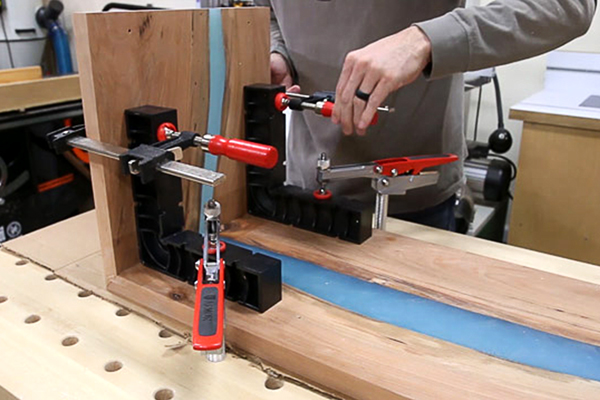

Cut and Join the Waterfall Edge

- To cut the waterfall edge, use your table saw and crosscut sled. Tilt the blade to 45 degrees and make the initial bevel on the larger vertical piece.

- Flip the smaller top piece over and back and bevel it with a matching miter. Move the blade 90 degrees and precisely cut the larger piece for the base.

- With the miters facing down, line up the pieces and put a piece of packing tape across the seam.

- Fold up the miter and use the top to position and clamp down a pair of angle squares to the slab.

- Use 5-minute epoxy again, apply it to one side of the joint, fold up the miter, and clamp the top to the angle squares.

Assemble and Finish

- Let the epoxy set up over 24hours and take it out of the clamps.

- Do some final sanding before finishing.

- Apply a two-part oil-based finish to the slab to help the epoxy come to life.

- Mount the base upside down and shim the wood.

- Your Epoxy Resin River Table is ready!

Credit to the tutorial and photos goes to fixthisbuildthat

Ronix

16 March 2021