- 5min

- 9682

- 2 Opinion

Knowing the difference between brushless and brushed motor can help you choose the tool that best fits your needs and in addition to reducing maintenance and repair spending, maximize productivity and achieve the desired results in a shorter span of time. This article sheds light on the brushless vs brushed motor power tools advantages and drawbacks for you to make an informed choice.

It was during the early 1960s when the first brushless motors appeared on the market. In 2003, they found their way to industrial machines, and around 2009 they were used in power tools for the first time. These motors are a more efficient and reliable version of their brushed counterparts. Let’s dive deeper:

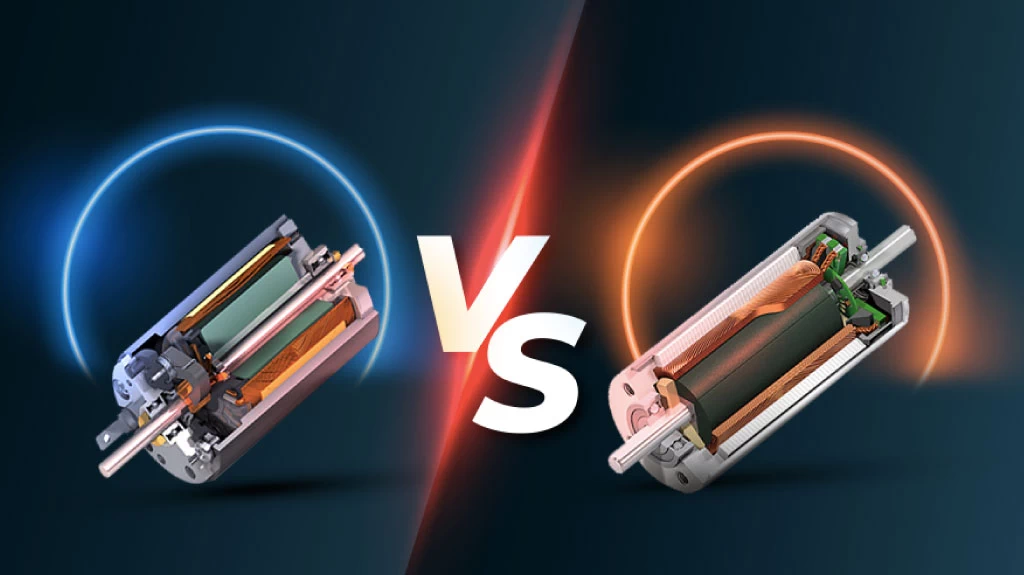

In a brushed DC motor, the armature is connected to a DC power source through a pair of carbon brushes and commutator rings. This is where all the brushless vs brushed competition begins because a brushless motor does away with carbon brushes and commutators and uses permanent magnets to rotate the motor’s rotor.

These two types of DC motors are different in terms of structure, function, and performance. Let’s compare the two categories and see which one wins the brushless motor vs brushed motor competition.

Difference Between Brushless and Brushed Motor

Without the consumable parts, like carbon brushes and commutators, brushless motors have a 50% longer life span and are free from sparks and friction, and energy loss.

These motors enjoy more efficiency, higher torque, and longer runtime which is an ideal condition for all power tools, especially the cordless ones.

brushless vs brushed tools competition intensifies when it comes to price, maintenance, and durability.

To choose between the brushed or brushless motor, you’d better explore the advantages and disadvantages of using each and make a trade-off if necessary!

What are the pros and cons of brushless motors?

Brushless motors are:

- Lighter in weight and more compact in size: The absence of mechanical brushes and commutators ensures the lightness of this type of motor.

- Less noise: The contact between commutators and carbon brushes generates a continuous noise in brushed motors. This is an annoying problem that you won’t face while using a brushless power tool.

- More power: The absence of commutators and brushes gives more room to add bigger winding coils. The bigger the motor, the more powerful they become.

- Minimum maintenance: In brushed motors, the brushes wear out over time due to constant contact with the power terminal, as the commutator rapidly rotates. So, they need to be replaced after a while. Meanwhile, brushless motors experience no contact between the rotor and stator, so they do not suffer from wear and tear and need no replacement of parts to function properly.

- Longer lifespan: no friction of mechanical parts and no heat released, help brushless motors last longer than brushed models.

Related Article : Electric motors

The new generation of DC motors, however, is not completely perfect and has its own drawbacks. It:

- Costs more: The overall construction of brushless motors costs more. Hence, the power tools equipped with them have much higher prices.

- Has a Complex structure: the wiring of brushless motors is quite complex; therefore, they are hard to repair in case of breaking down.

Advantages and disadvantages of brushed DC motors

If you have a drilling task at hand and after going through all the advantages of relying on a brushless motor, still can’t make up your mind between a brushless vs brushed drill, there is a good reason behind it. Because brushed models are not fruitless after all! Above all, power tools with normal DC motors have a more reasonable price than their brushless competitor. Furthermore, normal DC motors are ideal for extreme operating environments and heavy-duty tasks, and fixing them can be easily done by simply replacing the broken brushes with new ones.

Without a doubt, all users want their tools to work for a lifetime. But each power tool has its own limited life span and one day you would eventually need to replace it with a new one. Having said that, buying a brushless power tool can guarantee more durability, efficiency, reliability, and much more.

If between brushless vs brushed motor power tools, you’d prefer the former, Ronix Lasing Series is worth checking out! It contains five-star cordless tools, all equipped with high-quality brushless motors that ensure a powerful, secure, and enjoyable operation, whether drilling in concrete or cutting the grass! The good news is that the motor of each one of these tools is powered by a 20V lithium-ion battery that is compatible with all the other products in the series.

FAQ

Are brushless motors better than brushed ones?

When it comes to efficiency, durability, and power, brushless motors outmatch the brushed ones.

What are the disadvantages of a brushless motor?

Compared to brushed ones, brushless motors are high-maintenance and much more expensive.

Are brushless motors faster than brushed ones?

Due to less friction inside, brushless motors tend to be faster than brushed ones.

Ronix

4 November 2020

Comfortabl y, the post is really the freshest on that deserving topic. I harmonise with your conclusions and also will thirstily look forward to your next updates. Just saying thanks will certainly not simply be acceptable, for the extraordinary clarity in your writing. I will directly grab your rss feed to stay informed of any updates. Gratifying work and much success in your business dealings!

I got what you mean , thanks for posting .Woh I am happy to find this website through google.