- 8min

- 5051

- 0

The diversity of rotary tool uses has turned this tool into an all-purpose labor-saving solution for professional woodworkers, metalworkers, jewelry makers, hobbyists, and DIY enthusiasts.

There is a misconception that the use of rotary tools is limited to carving, sanding, and polishing wood but we are here to prove you wrong! So, keep reading to explore all you can do with your tiny Army of One!

First things first:

What Is a Rotary Tool?

Think about a versatile power tool that is easy to handle and is great for intricate and detailed work. What comes to your mind? How many tools can you name? Stop racking your brain because only a rotary tool is 100% fit for this job description.

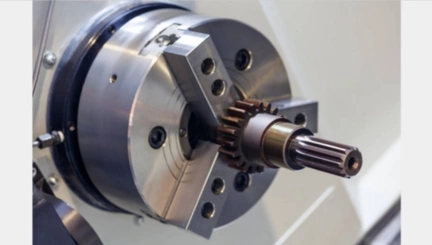

Popular among professional users and homeowners alike, Rotary tools are multi-functional devices that work by rotating tool bits and accessories like cutting wheels, sanding bits, and polishing tools that are mounted on a spindle with a mission to take care of grinding, cutting, and polishing tasks on different scales.

Rotary tools come in different power levels and designs, but they all share a fundamental feature, which is spinning at high speed to complete any task. Most of them can rotate with a speed of 20000 RPM while some others can spin faster, up to 35000 RPM.

As rotary tool uses are varied, they come with a speed control knob on the body which can be a slider or a couple of buttons that you can use to customize the rotation speed in accordance to the requirements of your project and the material at hand.

Types Of Rotary Tools

There are 3 different rotary tools which are basically same when it comes to function but different in their source of power.

Corded rotary tools provide a consistent power ideal for heavy-duty tasks and the ones that take long to complete. Cordless models offer more maneuverability and convenience while the ones that work with pedals leave the users hands free and are the best choice for tasks which require more control and precision.

In short, there are 3 types of rotary tools.

- Corded: A more consistent power for heavy-duty tasks

- Cordless: more portability and comfort

- Foot-operated: higher precision and control

Rotary Tool Vs Die Grinder

Before getting to rotary tool kit uses, let’s clarify another misconception. My friends, rotary tools and die grinders are by no means interchangeable! They might both be high-speed rotary power tools that look slightly the same but they different in many aspects.

Let’s take a closer look:

- Rotary tools: smaller, faster, more versatile, more prone to overheating, suitable for more precise and intricate tasks

- Die Grinders: Larger, more powerful, for heavy-duty applications, less expensive

What Is a Rotary Tool Used For?

Now it’s time to explore the diverse Uses for rotary tool. As mentioned above, these tools can be used in many tasks and applications, and adapting them for different situations is as easy as changing the tool bit!

Here is a list of uses for a rotary tool:

· Grinding

Thanks to various grinding attachments such as abrasive stones that come in different shapes and level of roughness, you are able to create sharp edges or eliminate them by your rotary tool. This function comes handy when you want to grind down the rough edges of a metal workpiece, sharpen kitchen knives, shears, and scissors, or clean old and rusty tools and objects.

· Cutting

One of the most important rotary tool uses is cutting. Here’s the instruction you’ve been looking for:

- To cut wood, drywall, plasterboard or similar things, use the straight bits

- To trim plastic or metal parts, use the cutting wheels

- To make fine cuts on hard metals like steel, use the carbide burrs.

We cannot say enough about the versatility of these power tools. Sometimes even the Plumbers use them to cut through tough material in confined spaces. So, no matter what you do, you could really use a rotary tool in your toolbox!

When using rotary tools as a cutting solution on metal, however, it is highly recommended to apply some cutting oil on the surface. That way you can reduce heat and increase the efficiency of the carbide metal-cutting wheel.

· Carving

To do engraving and carving on different materials such as wood, plastic, metal and stone, having a tool as small, comfortable and versatile as rotary tools is a must-have.

All it takes is changing the bit and attachment. carbide bits are ideal for wood and plastic and diamond-tipped bits are the preferred choice for metal, glass and stone workpieces.

· Glass Engraving

Glass working is an intricate and popular art which many people do as a profession or even a hobby. The use of rotary tools has made the whole practice easier and more enjoyable.

To start etching, carving, and engraving on glass, you need to be trained and use special bits. So, use diamond-tipped bits, which are made of steel with diamond grits embedded in the surface. this way you can easily cut and remove the glass without breaking it or injuring yourself.

You should also keep the temperature of the tool in check. Carving and engraving on glass might heat the bits up.so, it’s a good idea to have a glass of water by your side to dip the bits in it regularly in order to cool them down. If you are etching on a glass tumbler or jar, you can fill it with ice-cold water. This will prevent the workpiece cracking due to excessive heat.

· Drilling Holes

The long list of rotary tool kit uses also includes drilling into soft material like drywall and gypsum board ceilings that demands using the proper bits and router bits.

Although these power tools can be used to drill but they are not as strong as electric drilling machines. So, don’t you ever use one on hardwood and metal pieces in order or else you’d damage the tool.

· Sanding

Uses for a rotary tool are not limited to small and light tasks as far as you use them for sanding moldings or little details. There are so many sanding attachments for this power tool like band, flap wheel or abrasive buff which you can use to complete your tasks. the results will impress you.

· Polishing and cleaning

Rotary tools are do-it-all kind of devices and with tool bits like wire brush, polishing point or polishing wheel you can use them to clean lot of things including silverware, jewelry or old objects.

If you are a pro, go ahead and start polishing. Otherwise, you might want to watch some tutorials and read some instruction on how to apply wax to the bits in order to perform an efficient polishing operation.

What you read above on the uses for rotary tool, is just the tip of an ice berg as you can do much more with this army-of-one tool. “The sky’s the limit!”. Pick it up and you can sharpen your chainsaw’s chain, fix an old kitchen rack, cut curves into the tiles of your bathroom and complete many other tasks efficiently and effortlessly.

Related article: best hammer drill , best rotary hammer drill

How To Use a Rotary Tool?

Since rotary tools have fast-spinning motors, they can be dangerous, if mishandled. They might spit off ultra-tiny particles that can be hot or sharp, while cutting and grinding. To stay safe always have the following safety tips in mind while working with these tools:

- Put your goggle on before starting the tool. The last thing you want is flying debris or sparks (when working on metal) hurting your eyes.

- Don’t forget earplugs or headphones. Some models can be pretty loud.

- In case of working with fiberglass and other sharp materials, make sure you wear gloves or other kinds of skin protection.

- Long hair might easily get caught in the machine. So, if you do not want to go through such painful experience, make sure to put your hair in a ponytail or a bun.

- If the material you are working is prone to make a lot of dust, use the tool in a well-ventilated room and wear a face mask.

- Hold the tool with both hands for more control

- To have a stable grip, it is recommended to turn on the tool before bringing it in touch with the workpiece

FAQ

what is a rotary tool?

Rotary tools are multi-functional devices that work by a high-speed rotation of tool bits and accessories that are mounted on a spindle.

what is a rotary tool used for?

A rotary tool is used for a wide range of tasks from cutting, grinding and glass engraving to carving, sanding, polishing and cleaning.

Ida

31 October 2020