- 8min

- 5348

- 0

If you intend to buy a power tool, you should pay attention to water resistance, dust resistance, material hardness, and other physical factors. Nowadays, several mechanisms and standards have been designed to standardize and evaluate these physical factors.

Having a water-resistant power tool guarantees their resistance and long service life. In this article, we explain in detail about what waterproof power tools are. We will also shortly talk about hand tools. Our goal is to answer every question you might have on this subject.

Why Do We Need Water-resistant Tools?

Water resistance is an important factor in ensuring the durability of your power tools or hand tools. There are many situations in everyday life where tools could come in contact with water, such as rainy days, wet environments, plumbing tasks, etc. Water is dangerous and it can cause power tools to malfunction or short-circuit. It also causes corrosion or rust in the case of hand tools.

All these risks make water resistance such an important feature for power tools, hand tools, or any other equipment that you would use on a DIY or professional task. Water-resistant tools provide the users with safety and they are more durable.

What Do We Exactly Mean by a Water-resistant Tool?

Simply put, water-resistant tools are power tools and hand tools that are designed to withstand different levels of exposure to water. Waterproof tools are different from water-resistant tools.

Let us now talk about the history of water resistance in tools and give you more context. The exposure of human beings and the tools they use to water led to a series of inventions in the design of standards and mechanisms for power tools.

Making completely waterproof tools turned into an engineering challenge. The IP code was a product of this engineering challenge. The IP code was a consequence of these engineering efforts. The IP code gives ratings of how equipment and devices are resistant to solid foreign materials as well as water.

What are Waterproof Power Tools?

The term “waterproof” usually refers to products that can withstand any level of exposure to water. These products can be submerged underwater and still function properly. There are not many brands in the market that make truly waterproof power tools.

look at all about best quality power tools.

There are a few brands however that specialize in manufacturing tools that can be used in underwater environments. These tools naturally have the highest IP scores. The higher the IP score, the harder it is for foreign solids and water to penetrate into the housing of the power tool. Resistance to water in different tools, machines, and equipment is also called watertightness.

What Are Waterproof Hand Tools?

Being water-resistant has a different function and meaning for hand tools as opposed to power tools. Hand tools, like power tools, don’t have electrical components inside them that could get damaged and make the tool obsolete.

Hand tools are made of different types of metal that could get corroded or rusted. The main element that is essential in making these tools waterproof is their coating. Because of this, Water-resistant hand tools (waterproof hand tools) are ideal for jobs that are done in wet environments or around water like plumbing.

Keep Your Power Tool Water Protected

The ideal place to keep your tools is undercover and away from the possibility of getting them wet. If you must leave your tools outside, placing them on a waterproof surface, such as a tarp, is a good short-term option. It’s also a good idea to store the tools somewhere higher if possible to minimize water getting on the tarp they’re on.

What is the IP Protection Rating?

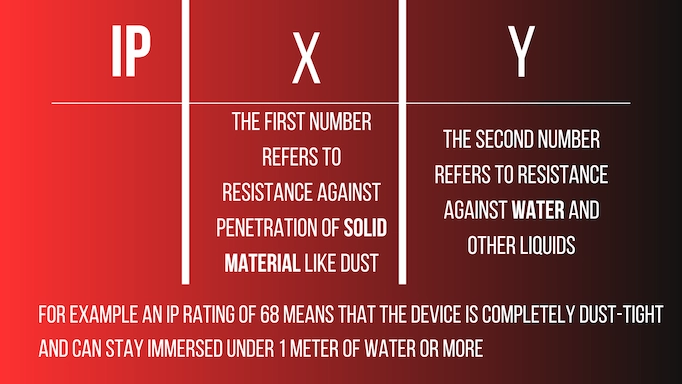

The IP protection rating is a two-digit rating that is applied to the housing of a mechanical or electrical element and provides customers with a clear indication of the resistance of a tool to various types of unwanted intrusions, such as water, dust, etc.

The International standard IEC 60529 was developed to standardize IP ratings of different equipment such as electrical and electronic equipment, cameras, sensors, tools, industrial equipment, and machinery.

This standard gives numerical specifications to classify equipment according to the level of protection that its container materials provide against the ingress of foreign materials. By assigning different numerical codes, the degree of protection of the equipment can be identified quickly and easily. The first number (numeral) of the IP rating refers to protection against solid foreign objects and the second number refers to protection against water damage.

How to Keep Your Tools Safe from Water Damage?

The ideal place to keep your tools is in a protective cover and away from the possibility of getting them wet. If you must leave your tools outside, placing them beneath a waterproof surface, such as a tarp, is a good short-term option. It’s also a good idea to store the tools somewhere higher if possible to minimize water getting on the tarp they’re covered in.

Are Hammer Drills Waterproof (Or Any Other Type of Power Tool for That Matter)?

Hammer drills, or any other type of power tool for that matter, are not usually designed to be waterproof. Power tools are made for being used in dry environments.

Some power tool companies make more water-resistant power tools, but even those companies do not advise their tools to be exposed to water. In the next next section though, we will talk about certain power tool companies that make specialized tools that can be used underwater.

Can I Use a Cordless Drill in the Rain (Or Underwater)?

As with any other kind of tool, the answer to this question depends on the IP rating of the tool that you own. In the power tool market, there are even waterproof cordless drills that are made for professional constructors or ship crew who need portable electric drills for operations in wet or underwater environments.

Related Article: What Do You Know About RPM the Rotational Speed in Power Tools?

These waterproof power tools can drill deep in salt, fresh, or chlorinated water. The waterproof drill is ideal for building and repairing docks and boat hoists. These tools can be used in and around swimming pools and aquariums for boat and yacht maintenance, and installing aquaculture and scientific equipment in maritime environment.

There are also some manufacturers who produce waterproof power tool battery chargers that can be safely used outdoors or underwater. They feature dust-resistant housing that is sealed and waterproofed. These battery chargers usually have an IP67 rating.

Having said that, there are batteries and water-resistant power tools in the market that should never be directly immersed in, or exposed to rain or water.

How to Make Your Cordless Power Tool Water Resistant

If you know how to open up your tool, you can easily make your tools waterproof (water-resistant). All you need is conformal coating which is material that provides electronic components with protection from environmental factors. There are different types of conformal coating based on the type of material such as lacquer based.

After you open your tool, you just need to spray one of these coatings inside the tool, and the battery. Spray the coating a couple of times at least to make sure that every surface that needs protection is coated.

Conclusion

Although in today’s global market, there are brands that make water-resistant power tools that can withstand short amounts of exposure to water. However, even these tools should never be submerged in water or exposed to rain. Some manufacturers also make waterproof power tool battery chargers that may be used safely outside or underwater. Although, these manufacturers are the exception.

FAQ ❓

Is it possible to use Power Tool Water Resistance in the rain?

Your power tools may appear to be well-sealed and waterproof, but even a single little raindrop can do catastrophic damage to the equipment and the person who is handling it.

Are there any power tools that are water resistant?

Although certain equipment and batteries are water resistant, they should never be immersed or left outside in the rain.

Is there any difference between waterproof and water resistant?

Water-resistant refers to different levels of resistance to water exposure, from vertically falling water drops to complete immersion in water. The term waterproof usually refers to tools and equipment that can withstand complete submersion underwater.

Can you use a cordless drill while standing in water?

Never use a cordless drill while standing in water. Always check the manual of your tool. Most tool manufacturers do not recommend this action even if their tools feature some level of water resistance.

Can you use a pneumatic drill underwater?

Using pneumatic tools underwater does not come with the same level of risk as using electric tools. But again, you need to check with the information that the tools manufacturer will give you about the water-resistance of their tools. Fresh water is generally okay, in most cases.

Farivar

12 December 2021