- 6min

- 32677

- 0

When an operator goes to the market to purchase a power tool, such as a drill, he must consider several decisive specifications of the apparatus in question, such as power, speed, torque, etc. In fact, the higher the power, speed and torque, the better the result. In this article, we focus on the topic of rotational speed, an important factor in getting better performance from power tools.

What Is Rotational Speed (RPM)?

Rotational speed, in terms of the electric motors, is the number of rotations of a tool per unit of time and is measured in revolutions per minute (RPM). In fact, RPM is a unit of measure used to show the no-load speed or frequency of a power tool.

📌 The turning speed is considered an important factor depending on the type of work that we are going to carry out. Therefore, when we use an electric machine to work on hard surfaces such as concrete, we are interested in opting for more revolutions per minute.

This speed also has a direct relationship with the type of tool we use. For example, cordless drills typically offer a maximum speed of around 2000 RPM, while most corded drills typically operate at a speed of 3000 RPM.

What Is the Difference in Turning Speed and Torque?

The concept of tightening torque expresses the amount of rotating force produced by the motor of a power tool. As an example, the rotary force of a screwdriver is used to tighten screws, nuts, or anything similar. In another saying, torque, which is measured in terms of Newton meters (Nm), is the force dedicated to turning an object and is the best indicator to find out the practical power of a power tool.

However, the rotational speed, as the name describes well, shows the rotational speed of an electric motor. For example, the higher the RPM of a drill, the higher the speed of the bit.

📌 Important note: Torque and rotational speed are not only different things, but they also have a completely inverse relationship. In simple terms, when a power tool offers high torque, it will have a low turning speed, and vice versa.

Why Do Some Tools Have Two Mechanical Speeds?

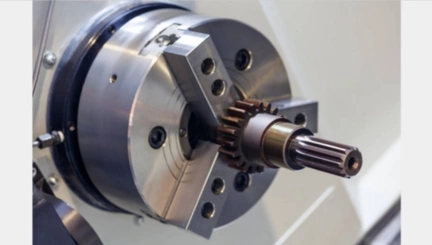

Certain power tools, such as drills, rotary hammers, screwdrivers, etc., offer two mechanical speeds, highly applicable for different types of work. In fact, these machines benefit from a special gear that provides two settings for the spin speed: one slow and one fast.

🔷 So, in a double speed electric drill, the first setting is slower, suitable for very hard materials such as metals. For its part, the second configuration is faster and its application is more appropriate in softer materials such as wood, or even in the drilling of concrete.

Or in a rotary hammer, when we want to drill a masonry surface, such as concrete, we activate the percussion system of the machine, the more times per minute the machine hits to break the concrete, the better, therefore speed 2 is more appropriate since the The higher the RPM (rotations per minute) of the machine, the higher its GPM (strokes per minute) will also be.

Drilling RPM

Drilling RPM is determined by the material’s cutting speed as well as the drill bit’s size. With the size of the bit, the RPM setting changes. To maintain the necessary surface footage, the RPM needs to rise as the drill bit grows smaller. Let’s look at the wheel as an example. Consider the drill bit to be a wheel, and the cutting speed to be a measurement. To cover the same distance in the same amount of time as a smaller wheel (drill bit), a larger wheel (drill bit) must turn fewer rotations (drill bit). As a result, larger drills must be operated slower than smaller drills in order to maintain the necessary cutting speed.

Learn it all about ergonomic power tools completely.

The color of the chip is the best indicator of correct and wrong cutting speed. The chips from a high-speed steel drill bit should never become brown or blue. Straw-colored chips indicate that your cutting speed is at its optimum for your cutting circumstances. Chip colors can range from amber to blue when utilizing carbide, but never black. If you see a dark purple tint, it means you’ve reached the limit of your abilities.

Drill Torque and Rotational Speed

The interaction between torque and rotational speed in cordless drills is the reality. In drills, torque and rotational speed are inversely proportional. As you raise your speed, your torque decreases. As a result, you have less torque available while drilling at fast speeds. When you drill at a low speed, you can get the greatest torque out of the drill.

That’s not the case with an impact driver, which increases power as you accelerate. That’s only one of the major distinctions between a drill and an impact driver.

FAQ ❓

What is the spin speed in power tools?

It is the number of rotations of a tool per unit of time and is measured in revolutions per minute (RPM).

What is the difference between the turning speed and the tightening torque?

The first shows the rotational speed of the motor, but the second shows the amount of force that the electric motor produces.

What does RPM mean?

It is a unit of measure used to indicate the frequency or no-load speed of a power tool.

Conclusion 📜

In conclusion, the turning speed is about the number of revolutions of a tool per unit of time. It is measured by revolutions per minute (RPM) and is considered an important factor in increasing the performance of power tools. The rotational speed is completely different from the tightening torque, which shows the rotational force of the electric motor. Some power tools also provide the double speed mechanism, which makes it possible to use them in different types of work.

Ronix

13 December 2021