- 9min

- 5434

- 0

One of the most essential tools in the field of woodworking is the table saw. These tools are extremely versatile and they come in a wider number of various types. Different types of table saws are mentioned in different categories here in this article along with their features to help you find the one you need.

Whether you’re a DIY enthusiast or a professional, the information in this article can help you understand the distinctions between jobsite, contractor, hybrid, cabinet, sliding, min, and compact models as well as some other categories. Some categories could be overlapping.

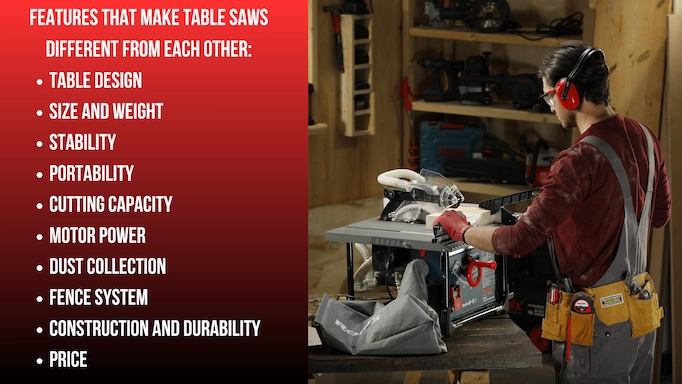

All of these types of table saws are mentioned along with their features. Each different type of application requires different features. The differences between types of table saws are as follows:

- Table Design: One example of how these tools are different. For example, cabinet saws have an enclosed cabinet base, while job site saws are designed for portability with a more compact table.

- Portability: This is one of the main differences between different types of table saws. Jobsite and contractor saws are designed with features like foldable stands and wheels which makes them more portable while cabinet and hybrid saws are generally less mobile.

- Size and Weight: Table saws come in different sizes and weights while smaller and lighter models like jobsite saws prioritize ease of transport.

- Stability: This is an extremely important factor when it comes to different types of table saws. A more stable saw helps you get more accurate and better results overall when cutting. More portable saws usually are less stable.

- Cutting Capacity: This is a factor that is determined by the size of the table and its distance from the blade to the fence. This varies across different models. Cabinet and hybrid models usually have larger cutting capacities compared to job site and contractor models.

- Motor Power: The power of the motor influences the cutting capabilities of the saw. Cabinet and hybrid saws usually have more powerful motors, allowing them to handle denser materials more efficiently than other types of table saws like a contractor or job site models.

Other important factors that distinguish different models from each other are:

- Dust Collection

- Fence System

- Construction and Durability

- Price

Safety Note: If you are a beginner and are considering getting a table saw, make sure you know how you can safely use these saws. Even with modern safety features like riving knives, blade guards, and rip sticks, you still need to know how to operate these tools safely and properly. Make sure you also use them with proper PPE.

Mini Table Saw

One of the outliers out of all the different types of table saws is the mini table saw. These tools are designed for small-scale applications that require a tool that matches the scale of these operations and can provide the required amount of precision. These table saws are always placed on top of a table because of their size! Mini table saws are used for small-scale woodworking projects, model making, or crafting.

The term “mini table saw” refers to a specific type of table saw but if you are looking for a regular saw that is simply smaller or more compact, you should probably look at the section “compact table saw”.

Portable Table Saw

Portability is a spectrum when it comes to table saws. Manufacturers make these tools portable in different ways. Table saws that are placed on top of a table are exceptionally common types of portable table saws. These table saws can only be used when you have a table to put them on.

Some manufacturers make table saws portable by adding foldable stands. Others make table saws portable by adding wheels. In the case of portable table saws that have wheels. The latter portable table saw types usually come with two wheelless legs and two airless wheels which are stabilized like a wheelbarrow.

Stationary Table Saw

This term is a broad one that refers to any model that is kept and fixed in one place. These table saw types are used by more professional users because they are more powerful and are more stable. These saws are larger and heavier than their portable counterparts.

Stationary table saws are usually more powerful and stable and they are used by woodworking workshops and factories. Portable table saws on the other hand are usually used by DIYers who don’t have a dedicated space or by job-site contractors who need mobility.

Stationary models have more powerful motors. They have a larger weight and that is what makes them a lot more stable. These tools also have a much larger table surface for large workpieces.

Cordless Table Saw

Corded and cordless table saws are the main types of these tools in terms of the way that they are powered. Cordless models are more portable and convenient than corded (Ronix 5605 Electric Table Saw 2000W-315mm) models. They are also safer since there will not be any risk of accidentally pulling the cord while working.

The downside of cordless table saws is that they are less powerful than corded models. Always make sure that you have spare batteries that are full when it comes to cordless table saws. Cordless power tools in general have come a long way though. Batteries have gotten a lot more powerful as well.

Contractor Table Saw

Contractor table saws are portable tools that are designed for contractors and carpenters who need a powerful tool to take to the job site. What makes contractor models so unique is the fact they are designed for both power and portability. These tools are designed to be more heavy-duty than other portable table saws types and they are larger than compact portable models.

These tools usually feature a motor with a horsepower ranging from 1.5 to 2.5, which allows them to handle a wide range of cutting tasks. The motor of the former type is mounted on the rear of the saw on a stand separately as opposed to cabinet models which have a motor that is inside a cabinet.

Compact Table Saw

These types of table saws are the most lightweight and smallest out of all the portable table saw types. These tools are ideal for people with limited space or people who need an extremely portable option to bring to the job site. Nowadays compact table saws possess enough power to handle a wide variety of tasks. A lot of compact models feature a folding stand or integrated carrying handles.

Jobsite Table Saw

These types of table saws are almost identical to compact portable saws except that they usually have more powerful motors. These tools are designed for portability and versatility which makes them ideal to use in situations where you need to move from one job site to the other.

These table saws can be set up more quickly than other table saws and they come with adjustable fence systems for more accurate and precise cuts. These saws also come with features that facilitate in easy adjustment of the blade height and bevel angles.

Hybrid Table Saw

These types of table saws are tools that combine elements of both contractor models and cabinet models. They are stationary models that are built like a cabinet saw in appearance but they have the insides and the motor of a contractor saw.

These tools have a more stable construction than other contractor saws. They are also relatively more powerful than contractor models. These tools also have superior dust collection systems compared to contractor saws. These saws fall into the midrange price category usually. They are more expensive than typical contractor saws but they are more affordable than cabinet saws generally.

Cabinet Table Saws

These types of saws are powerful and heavy-duty woodworking tools that are designed for professional woodshops and serious hobbyists. These tools are named “cabinet table saws” because they are enclosed within a base or cabinet that contains the motor and other internal components.

Cabinet models are usually heavier and larger than the contractor or job site saws. This makes them more stable, reduces vibrations, and ensures smoother and more precise cuts. These models are usually equipped with powerful induction motors and they offer a power ranging from 3 to 5 horsepower. The amount of power allows these tools to cut through thick and dense materials with ease.

One thing that separates cabinet table saws from other models is their precision and accuracy. These tools have fences that can be easily adjusted for different cutting tasks.

Sliding Table Saws

Out of all the different types of table saws, these tools are some of the most unique ones. They feature a sliding table mechanism. This sliding mechanism can be used to move the workpiece parallel to the saw blade. Using a sliding model, users can move the workpiece through the blade without having to move the material manually. These models make the cutting processes extremely simple.

Sliding models are preferred for professional and heavy-duty settings. These modes are larger and they come at a higher price point compared to regular table saws. The choice between a sliding model and a regular model ultimately depends on the requirements and preferences of the user.

If you are looking for affordable high-quality power tools including table saws, take a look at the catalog of Ronix with a lot of variety for everyone.

FAQ

What types of projects is a table saw good for?

A table saw is a versatile and powerful tool that helps cut wood for a wide number of carpentry and woodworking applications. Ripping cuts, bevel cuts, miter cuts, and routing are all possible.

What are 3 common types of table saw blades?

All-purpose (combination) blades, rip blades, and crosscutting blades are some of the more popular table saw blades.

Ronix

20 October 2024