- 10min

- 32008

- 5 Opinion

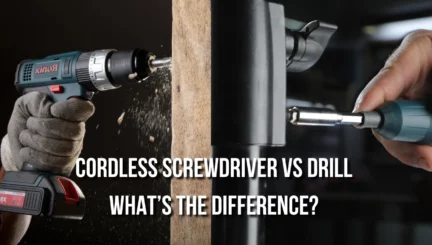

Drills and impact drivers are two of the most common power tools used for almost anything. The main difference between impact drivers vs drills is the way that they work. This is why these two tools also have different advantages and disadvantages. Knowing the difference between these two tools can help you choose the best tool for every task at hand! By choosing the best tool every time, you will also be able to finish your work faster and/or more accurately.

In this article, we will talk about what’s different between impact drivers and drills comprehensively. We will talk about the basics of each tool and their pros and cons. Finally, we’ll talk about when to use impact drivers vs drills.

Note: When we talk about drills in this article, we’re mostly talking about cordless drills (Ronix 8618)!

What is an Impact Driver?

An impact driver drives fasteners with an impacting mechanism instead of the rotational mechanism of a drill. Simply put, there is an up-and-down motion inside an impact driver which is converted to a rotational force. Imagine a hammer hitting the end of a wrench that is attached to a screwdriver which then turns a screw. Now imagine the same thing happening thousands of times more.

Related Article: Best Impact Drivers

Pros

- Improved Torque

In comparison to drills, impact drivers provide significantly higher torque. This is ideal for driving larger fasteners. Remember that the higher torque these tools provide doesn’t mean that they are faster necessarily.

- Driving Large Screws

Because of this higher torque, they can be used for driving much larger screws. To drive these types of screws with a drill, you would usually need to pre-drill a hole. This is the main benefit of impact drivers vs drills.

- Less Kickback

An impact driver delivers force through pulses rather than a continuous motion and if an impact driver gets stuck, it moves a small amount and stops every time.

If drills get stuck, on the other hand, they move in the opposite direction with much more force and cause greater kickback because of their constant rotational movement and their movement has to be stopped using an auxiliary handle to prevent hand injuries.

- Doesn’t Strip Large Screws

Stripping usually happens when there is a misalignment between the driver bit and the screw head. Stripping makes the screw unusable. Because impact drivers deliver force through short bursts rather than a continuous force, even if the bit and the screw head are misaligned, this force doesn’t go all the way at once and cause the bit to get stripped.

- Impact Driver Bits Are Quick to Change

Impact driver bits are hex bits. You can change the bit on your driver using a quick-release sleeve and then put the new bit in almost instantly. This feature can help you switch tasks much more easily.

Cons

- Speed Control (Less Speed Control)

There’s almost no speed adjustment on impact drivers. Some drivers come with speed control triggers. Some impact drivers like Ronix 8906 could have a 3-speed selector. However, in comparison to drills speed adjustment on these tools is much inferior. This is one of the main downsides of impact drivers vs drills.

- Using Drivers for Drilling

Drilling with impact drivers is technically possible using impact-rated drill bits. However, in the absence of speed adjustment on impact drivers, drilling precise holes is challenging. Drills are almost always the superior tools for this purpose, especially for materials like glass or tile. The impact driver sometimes can’t maintain a bit in place on these materials or could damage them.

- Stripping Smaller Screws

The force that an impact driver produces is just too much for small screws. It can overdrive or strip these smaller screws. For turning smaller screws, a drill is an ideal choice because of its speed adjustment.

What is a Drill?

A drill or a drill driver is probably the most popular power tool out there. These tools are also extremely versatile. They are used for drilling holes of every dimension and they can be used for fastening most types of fasteners. Drills work by creating a constant rotational force. This constant rotational force is perfect for drilling holes.

One of the stark contrasts between drill drivers vs impact drivers is the fact that they usually produce a higher rotational speed while impact divers produce higher torque. This higher torque is generally better for driving fasteners while the higher rotational speed of the drills is ideal for drilling holes.

Note: In this article, when we talk about drills we mean cordless drills. This is because most of the corded (electric) drills don’t have some of the features that we are gonna talk about like the selector on the gear or the clutch.

Pros

- Drilling Holes in Every Material

Drills provide a constant rotational force which Is ideal for drilling precise holes. They also have a higher rotational speed. Don’t confuse rotational speed with torque. Their torque and speed can also be adjusted to match different materials. For example, you need a lower speed for drilling in metal than drilling in wood. This is the main advantage of drills vs impact drivers.

- Speed Control

A drill comes with a gearbox selector as well as a clutch. With these features, you can adjust the torque and the speed to match the task at hand. Different tasks require different speeds. A drill’s speed control simply gives you a lot more versatility in both drilling and driving tasks.

- Better at Driving Small Screws Vs. Large Screws

The clutch and the gear selector on a drill allow you to adjust the speed and torque for your desired purpose. Using a drill on the low-torque and low-speed settings allows you to drive smaller screws without having to worry about stripping or overdriving the screws.

- More Variety in Bits

There is a larger variety of drill bits and driver bits for drills in comparison to impact drivers. You can use drills with specialized metal, concrete, or wood drilling bits. Drills can also be used with spade bits, Forstner bits, and hole saws to give just a few examples.

Cons

- Less Torque

Drills simply provide less torque than impact drivers. This is because of the sheer force of the impact mechanism on an impact driver. Remember that impact drivers are not faster but they have more torque which helps when you need a lot of force to overcome a high amount of resistance.

- Stripping Larger Fasteners

When turning large fasteners, drills sometimes don’t provide enough force to overcome the resistance and sometimes they will spin in place and become misaligned, causing the screw to get stripped. This is a big disadvantage of drills vs impact drivers.

One solution to this problem is pre-drilling before driving large fasteners. Impact drivers on the other hand give you enough torque to avoid this problem altogether.

- Kickback Is A Big Problem with Drills

The drill bit or the screw can get stuck inside the material. As a result, the drill will suddenly rotate in the opposite direction because of its constant rotational motion. Kickback is dangerous and can cause hand injuries if not careful. This is one of the downsides of drills in comparison to impact drivers.

When to Use an Impact Driver vs. Drill

Drills and impact drivers are both extremely useful tools for different tasks. Read more as we discuss the topic of when to use an impact driver vs a drill.

If you are wondering which of these tools to buy first, take a look at their different applications and decide which one is more useful to you. Both of these tools are equally useful and having both is the best option.

Use a drill if you want to drill holes, especially precise ones!

The main purpose of a drill is… drilling! Surprising right? Drilling in different materials requires a constant rotational force which the drill provides. The faster rotational speed of a drill vs impact drivers is an important factor in creating precise holes.

Remember that impact drivers have better torque but the rotational speed of drills is higher. The speed control on a drill is also extremely useful for this task. This is because drilling metal for example requires a slower speed.

Always use a drill for drilling holes into glass, tile, or thick metal sheets

Even though you can technically use an impact driver for drilling, there are certain instances for which you should almost never use an impact driver. Drilling into glass, tile, or thick sheets of metal is one of those instances. These materials could crack because of the impact mechanism of an impact driver.

Use an impact driver for fastening larger fasteners

Impact drivers are the best tools for fastening larger fasteners like lag screws or decking screws. You can even drive large bolts with these tools using an attachment that converts impact drivers to impact wrenches. This is because of their higher torque which is delivered in short bursts. By using impact drivers to drive larger fasteners, you will also avoid kickback, a common problem when driving larger fasteners with drills.

Use an impact driver when you just gotta drive screws!

When you’re on a screw-driving spree, you just need an impact driver! This happens a lot when it comes to jobs like carpentry. Carpenters sometimes need to fasten hundreds of screws in wooden structures or framing.

If you need to take out screws that are stuck, use an impact driver

Because of their higher torque, impact drivers are the perfect tool for taking out screws that are stuck. Using a screw-remover attachment, you can easily remove stuck screws from the workpiece using an impact driver. When comparing drivers vs drills, this is one of the most unique advantages of drivers.

Drills are the best for delicate and small screws!

Impact drivers have too much power for drilling smaller screws. They could strip or overdrive these screws. Drills on the other hand have speed control on the clutch. The best option for driving delicate or small screws is using the low-speed clutch settings on a drill.

FAQ

Can you use an impact driver as a drill?

It’s technically possible to use an impact driver as a drill with specialized impact-rated drill bits. However, impact drivers have shortcomings when it comes to drilling. They are not the best tool for tile, glass, or thick metal.

Can you use a drill to drive screws?

Yes, you can use a drill for driving screws. It’s one of the main uses of drills. Although, impact drivers are the better tool for driving screws, except for smaller and more delicate screws.

Arturo

11 August 2024

I bought an impact driver 12 years ago and never got one again. Drills are the best.

Impact drivers are much better now compared to 12 years ago. They’ve gotten better over the years and they’re going even further every year.

Come on! Why does my drill/driver drive screws faster then?? I don’t get it.

Impact drivers are only faster when it comes to large screws and especially bolts. Also, impact drivers are getting better and better every year

Interesting! I need to get my own impact driver soon!