- 13min

- 66392

- 3 Opinion

What is a bevel cut?

Being able to cut bevels, you can create beautiful woodcrafts like a picture frame. But what is a bevel cut? The angle between the face of a board and its edge is 90 degrees. If you change this angle to any angle other than 90 degrees, you will have a bevel cut. Understanding the differences between bevel and miter cuts will improve your woodworking to the next level. If you make these cuts on your stock on two sides, you will have a double bevel cut.

We have now given you a bevel cut definition. In the next section we talk about the miter cut vs bevel cuts. If you are a woodworker looking to understand the difference between bevel and miter cuts, in this article you will find it.

Bevel Cut vs. Miter Cut

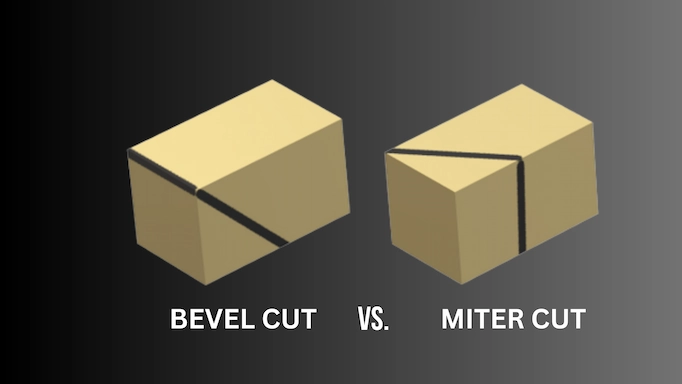

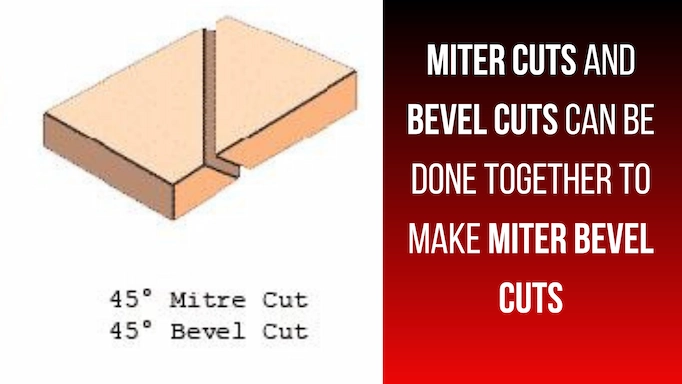

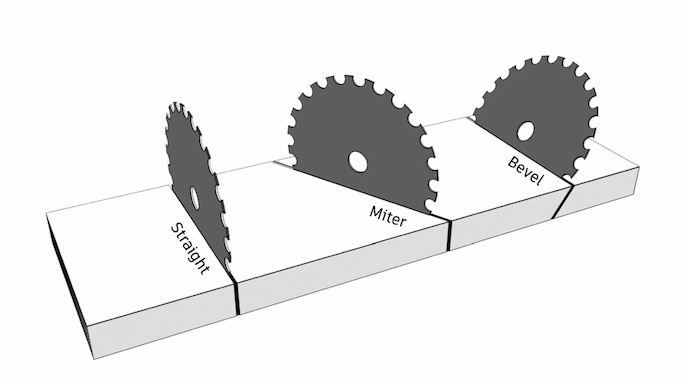

One of the things that beginners in the field of woodworking have a problem understanding is what is a bevel vs miter cuts. It is crucial to know the bevel cut meaning. Although they are both angled cuts, bevel cuts and miter cuts are actually different from each other. To understand miter vs bevel cuts, you have to look at the dimension of the angle. This is more visible when the wood piece you are working with has enough thickness, these two phrases find a clearer meaning.

If you cut a piece of wood diagonally on the face with a specific angle, then you will have a miter edge. Now if you cut the same piece of wood in depth and cut it with a specific angle, then you will have a bevel edge. The bevel cut and Miter are widely used in carpentry and woodworking. If you haven’t done this cut before, you’re missing out on its uses and advantages.

Making a bevel with a circular saw is just as easy. Almost every circular saw has a tilting baseplate that allows the angle to be set. The thumb screw or catch to loosen the tilt will be in front or behind the blade and off to the side, usually in line with the trigger.

Now that you have an understanding of a miter cut vs bevel cuts, let’s talk about what these cuts are used for.

Invest in premium wholesale miter saws to win customers over

What is a Bevel Cut in Wood Used for?

Now that you know what’s a bevel cut and you have an understanding of a mitre cut vs bevel cut, what are they used for? Bevel cuts in wood have various applications and purposes. One of the common uses of these cuts in wood is creating joints. The most common example of this application is when two pieces of wood that are bevel-cut at 45 degrees are joined together. Bevel cuts have other applications in woodworking such as safety, aesthetics, and preventing weathering.

How to do Bevel Cuts?

If you have just decided to start as a beginner woodworker, you will need to make sure that you purchase the appropriate wood-cutting tools. We will give you tips so that you can decide what kind of tool to buy to bevel cut wood.

There are some things that you should know when it comes to the tools for beveling your wood. You should always choose the right tools as well as the correct method for creating bevels in your wood stock. Taking your time when choosing a bevel method is a must to achieve your desired results.

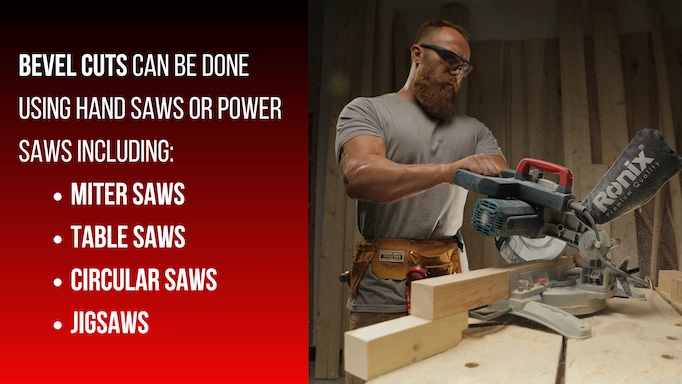

Bevel cuts can be done using either hand tools or power tools. If you want to do this woodworking task using hand tools you first need a hand saw: a coping saw, or a hacksaw for example. You also gonna need a bevel gauge for measuring your desired angle and also clamps.

Doing any type of cut on wood is much easier with power saws but you have to pay attention to safety. The most popular types of power saws for doing bevel cuts are miter saws, circular saws, table saws, and jigsaws. In the following parts of this article, we’re going to tell you how to make a bevel cut using each of the power saws.

Safety note: Power saws, especially table saws, are extremely dangerous. This article is specifically dedicated to talking about bevel cuts. We assume you already know how to safely and properly use every type of power saw that we will discuss in this article. If you don’t, you should look this information up!

How to Measure a Bevel Cut?

Every type of power saw provides you a way to tilt the saw blade and measure its angle. This task can be done on jigsaws and circular saws by tilting the baseplate. Circular saws and jigsaws have gauges for measuring the angle of the bevel cut.

Miter saws and table saws feature a knob that tilts the blade and a gauge that shows you the angle of the blade which helps you set the blade to your desired angle. Sometimes, the angle which these gauges show could be imprecise. To make sure that the angle is correct, you can use a bevel gauge.

45 Degree Bevel Cut

45-degree angles are the most popular angle for these kinds of cuts. 45-degree cuts are done to join two pieces of wood together. This angle is used frequently for making moldings and picture frames.

To make sure the blade on your power saw is adjusted correctly to 45 degrees, it doesn’t hurt to use two different pieces of scrap wood cutting them with your power saw and put them close to each other to see if they make a 90-degree angle when they are put next to each other.

30 Degree Bevel Cut

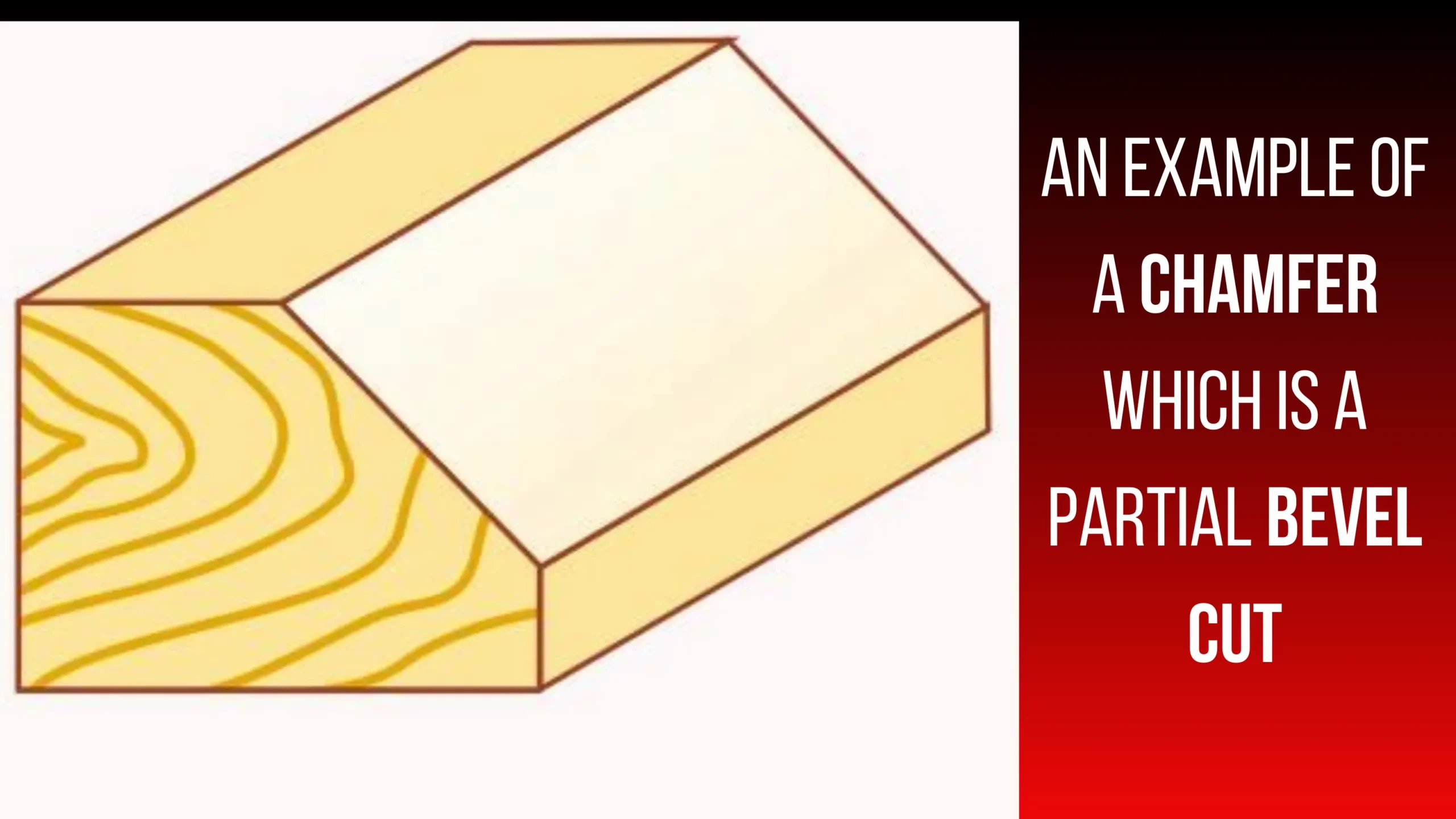

30-degree angle cuts are mainly used for aesthetics when making tables and furniture. 30 degrees is also a popular angle for creating chamfers, making moldings, and crafting wooden items.

60 Degree Bevel Cut

60-degree angled cuts are also one of the most popular cuts like 30-degree angled cuts. They are used for different woodworking and carpentry purposes such as creating chamfers, and certain moldings.

Bevel Cut with Circular Saw

Circular saws are not only used for straight right angles (cross-cuts). They can also be used for cutting bevel cuts. Circular saws have a baseplate (shoe) that can be tilted using a knob. When you tilt the baseplate, the angle of the saw blade itself changes. This angle can be measured using a gauge next to the knob.

Now that you know how to make a 45-degree bevel cut with a circular saw, or any other circular saw bevel cut, let’s talk about doing these cuts with other types of power saws.

Bevel Cut with Jigsaw

If you know how to do bevel cuts using circular saws, you basically know how to do them using jigsaws. To do a jigsaw bevel cut, you simply have to change the angle of the baseplate (shoe), similar to circular saws. This angle can be measured using a gauge next to the knob that tilts the baseplate.

Table Saw Bevel Cut

When working with table saws, you have to pay extra attention to safety. As we mentioned before, we assume you already have enough knowledge of using every power saw we mentioned. If you don’t know how to use your table saw safely, familiarize yourself with all the table saw safety tips before using one. Use proper PPE and make sure you use push sticks or push blocks to move the workpiece. Table saws are dangerous tools and they can easily injure you. If you ignore safety while using this tool, you could even lose a finger.

For making a bevel cut, table saws have an adjustment knob that tilts the angle of the saw blade. The angle can be measured using a gauge next to the knob. To make sure the bevel adjustment gauge on the table saw is accurate, you need to double-check with a bevel gauge (sliding T bevel).

After you change the angle of your table saw, you have to place your workpiece properly on the table saw depending on whether you want to do a rip cut or a cross cut. Before cutting your piece, do a test cut to make sure that the saw is accurate. Do not turn on the saw until you are ready to begin the operation.

Now that you know how to cut a bevel on a table saw, we can get to the final section of this article and talk about miter saw bevel cuts, or “mitre saw bevel cuts” if you prefer the UK spelling!

Miter Saw Bevel Cut

For doing a bevel cut, miter saws are perfect tools. Again, you should make sure of safety when using any type of power saw. First, you need to set up the angle of your miter saw using a knob that is usually placed behind the tool. As always, it’s worth double-checking the angle of your cut with a test cut or a bevel gauge.

After you’ve measured the bevel cut angle, it’s time to make the miter saw bevel cut. You should place your piece accurately on the miter saw base and against the fence and make sure to stabilize it. You have to set the miter gauge to 0 degrees.

After you’ve taken all these steps, you are ready to cut your piece of wood. After you’ve turned on the miter saw, you just simply “land it” slowly on the workpiece with the handle.

On miter saws, you can also flip the workpiece and use the miter gauge to make a bevel cut and then flip the workpiece back. Voila! You have a bevel cut!

Suggested Products:

Now that you know how to make a 60-degree bevel angle on a miter saw, or any other angle for that matter, let us talk about a good miter saw to buy.

Ronix Dual-Bevel Sliding Compound Miter Saw

One of the fastest ways to cut wood is using a miter saw. A compound miter saw has a fixed position saw with a blade that pivots only one way for angled cuts this is an economical choice for occasional use a dual bevel miter saw gives you additional versatility by tilting in both directions so you can easily make bevel cuts both ways this feature saves you time because you don’t need to continually turnover or reverse your material a sliding miter saw extends the cutting capacity of the saw substantially available in both compound and dual models the sliding feature allows you to move the blade forward and backward to increase the length of the cuts it can provide his feature saves you time because you don’t need to continually turnover or reverse your material. A sliding miter saw extends the cutting capacity of the saw substantially available in both compound and dual models the sliding feature allows you to move the blade forward and backward.

This motor can provide a maximum rotation speed of 4,200 rpm which results in high performance in various functions such as cutting wood at a 90-degree angle, as well as bevel angles and other required angles. Ronix miter saw motors are manufactured to ensure long life and high efficiency. Ronix 5025 and 5030 miter saws are equipped with a 2000-watt powerful motor. These compact saws can be transported to various construction sites and workshops with ease thanks to their lightweight design.

This saw is equipped with a two-way ruler and a movable screw clamp and contains a protective piece for user safety which allows the blade to appear only when cutting. This guard takes care of your hands from hitting the blade during cutting and even after cutting when the blade is moving.

One of the very important techniques in carpentry and wood cutting, whose presence causes high accuracy in work and achieves the desired result, is laser technology.

The laser pointer system is installed in the Ronix dual-bevel sliding compound miter saws 5025 and 5030 to notify the user of the exact location of the blade hitting the wood before cutting the wood and if necessary, change the position of the wood piece to the desired point. This feature is handy for cutting parts with longer range and at different angles.

The blade in this tool slides forward on its rails, which allows you to cut boards without having to take the board and flip it over. This saw is going to give you the ability to cut a lot longer than a compound miter cuts on boards without having to take all the time to realign, adjust, and flip the board over.

FAQ

What is a bevel cut in wood?

A bevel cut is a vertical cut that creates an angled incline on the cross-section that is created after cutting.

How to measure for a bevel cut?

If you are using handsaws to make a bevel cut, you need to measure your angles using a bevel gauge (sliding t bevel gauge). Power saws have bevel adjustment mechanisms and gauges to measure the bevel angle.

How to measure for a 45-degree bevel cut?

45-degree bevel cuts are the most popular bevel angle. You have to use a bevel gauge to measure the angle of your cut. This can be easily done with any power tool without needing any other tool but if you are using hand saws you need to measure the angle of your cut with a sliding T bevel.

What is the difference between a miter cut and a bevel cut?

Both of these two types of cuts are angled cuts. With miter cuts the blade cuts the material vertically but at an angle. Bevel cuts create an angled incline.

How to make a bevel cut with a miter saw?

There are two ways to make bevel cuts on a miter saw. One way to do this is to tilt the blade using a knob on the back of the miter saw. Another way to make bevel cuts is to change the miter angle, flipping the workpiece, making a miter cut, and flipping the workpiece back to its original position.

Ronix

31 October 2020

[…] How to make perfect bevel cuts in wood – Ronix Blog […]

Thanks for the post

Thanks, I’ve been looking for this for a long time