- 8min

- 10313

- 0

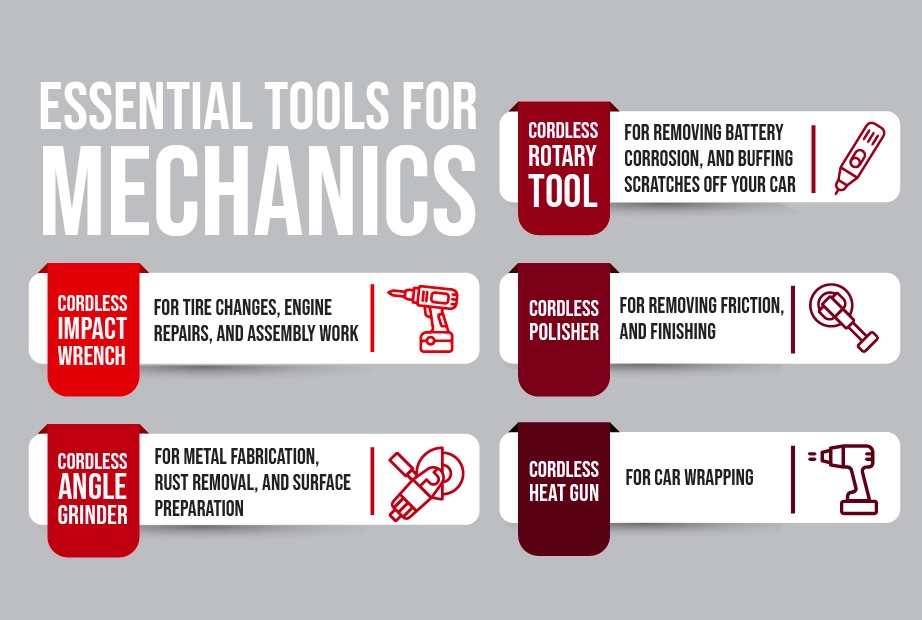

You may find many different power tools in every automobile repair shop, but do you know all about them? Probably not. Corded power tools are becoming less and less popular among artisans with the upcoming technologies in cordless tools for mechanics. For this reason, even in a car repair shop, you will find more cordless tools rather than corded power tools. This article will review the essential cordless power tools you may need in your fully-equipped garage for regular car repairs. Let’s take a look at them.

Cordless Power Tools for Mechanics

Mechanics’ cordless tools are used in different fields ranging from diagnosing problems, conducting repairs, and performing routine maintenance for automobiles, motorcycles, industrial machinery, aircraft, and more. So, the most important cordless power tools for mechanics can vary based on the specific tasks and needs of the mechanic, but here is a list of commonly essential ones:

Cordless Impact Wrench

There is probably no repair shop where you cannot find an impact wrench. For any high-torque situations, you will need a proper impact wrench and a set of sockets. However, the most useful feature is loosening lug nuts from vehicles and machinery like cars and trucks. Some people may mistake this power tool for an impact driver. To know how to distinguish them, you need the following facts:

- A conventional impact wrench can accommodate a 1/2-inch socket of various sizes that can fit a wheel lug.

- An impact driver has a 1/4-inch hex opening.

Before the popularity of cordless tools, pneumatic-powered impact wrenches were the most commonly used tools in professional garages. But as battery technology improved, cordless impact wrenches got better, brought prices down, and made themselves a viable alternative to the pneumatic types. The most popular feature of these cordless mechanics’ power tools is portability. You should have the ability to freely move around the vehicle and loosen the lug nuts as fast as possible, without the cables all around you.

Cordless Angle Grinder

As you may know, an angle grinder has different essential parts:

- A spinning wheel that is for cutting, grinding, and polishing

- A safeguard

- A housing

You may not see one in a garage or repair shop all the time, but there are many situations in which you will need one for sure. Removing rust or old paint might be the most used of a grinder.

You can use different sizes of wheels for this action to have the most accurate results. Since the angle grinder is made for cutting metal, the other purpose of a grinder is cutting out metal sheets, such as different parts of a car. On the other hand, having a portable angle grinder gives you the ability to have more control during the process.

Cordless Rotary Tool

Among all the cordless mechanic tools, rotary tools might seem too delicate for a large vehicle. However, they are super handy and efficient for many different tasks.

- Removing battery corrosion instead of a toothbrush or cutting a rusted clamp

- Buffing scratches off your car, truck, RV, or motorcycle

- Cleaning the dirt and smoothing out the scratch with a rubbing compound using the felt wheel in a circular motion

After the compound is dried, remove it with a soft microfiber cloth, and then apply the polishing compound. All these steps must be done in a circular motion, and you can achieve a very first look back on your car using only a rotary tool and some extra wheels. Furthermore, when this tool becomes cordless, you will have more control and you can work in different positions without the wire coming in the middle.

Cordless Polisher/Buffer

Before we get to the advantages of these mechanics’ cordless tools, we will briefly define the difference between a polisher and a buffer:

- A polisher is used for more aggressive applications, involved with more friction, and also using abrasive to even out the paint.

- A buffer is used to modify and improve the clear coat during a less harsh process, which brings out luster and a smoother finish.

It may happen by a carwash when they scrub off dirt with something abrasive, either a Scotch-Brite pad or a brillo pad, which leaves marking marks on your car paint. In this situation, you need a proper polisher to start with. The chosen polisher can be either rotary or dual-action, which could be described in another article.

You simply add some swirl remover to the pad for a light scratch, spray some polishing pad conditioner start to spread the polish around the scratch, and finally polish side-to-side the scratch. In the end, you will have a pleasant and lustrous finish that is incomparable with the original look.

In the whole process, a cordless polisher can have the same power but with more possibilities. You wouldn’t need to look for power outlets to start and no worries about the cable being in the way.

Cordless Heat Gun

Have you ever heard of wrapping a car? No, it is not for preparing a gift, but to have a new look for your vehicle and protect its paint. Car wrapping is another way to change the look of your car without spraying color all over again. This method can also be an alternative for complicated and more expensive painting. You only need a prepared and clean car, a vinyl film, a sharp blade, a squeegee, and a proper heat gun.

Among all the essential cordless tools for mechanics, you will need a powerful heat gun to apply a layer of plastic vinyl coating to heat it and make it stick over the top of the vehicle’s paintwork. There is an undeniable fact that corded heat guns are often used in vehicle wrapping centers rather than cordless ones. Because vehicle wrapping is a long process, and a cordless battery may not last until the end. But for confined and small spaces, a cordless heat gun is a must. Additionally, they are lighter and easier to carry around, so you will be able to work for hours without fatigue.

Related Article : Best Cordless Tools for Every Field and Task Out There

Pros and Cons of Cordless Tools for Mechanics

You got some general information about the essential cordless tools for mechanics. Now, you can explore their pros and cons in the table below.

| Disadvantages | Advantages | Tool |

|---|---|---|

| Requires periodic battery recharging.Some models may be noisy. | High torque for efficient fastening and loosening.Portability and flexibility for use in various locations.Reduced user fatigue with ergonomic designs. | Cordless Impact Wrench |

| Limited battery life.Noise and sparksSafety concerns with rotating discs | Versatility Increased mobilityUseful in tight spaces Quick and easy tool changesAdjustable speed | Cordless Angle Grinder |

| Limited power and cutting depth compared to larger toolsRequires frequent recharging Not suitable for heavy-duty tasks May produce vibrations | Compact and lightweight for detailed work. Easy to work withQuick tool changes | Cordless Rotary Tool |

| May require additional accessories for different polishing applications. | High mobilityErgonomic for reduced user fatigueSuitable for automotive detailing | Cordless Polisher |

| May not reach the high temperatures of corded models.Limited heat output compared to corded industrial heat guns | Adjustable temperature settingsQuick warm-up times | Cordless Heat Gun |

Cordless Power Tools for Car (Automotive) Mechanics

Cordless power tools are a must-have for car mechanics, giving them the flexibility and mobility needed in fast-paced repair jobs. Tools like cordless impact wrenches effortlessly handle lug nuts during tire changes, while cordless ratchets provide precise control in tight spaces. Cordless drills and drivers are versatile for drilling and fastening tasks, making routine maintenance more efficient. Battery-powered impact drivers are great for quick and precise screw and bolt driving, speeding up assembly and disassembly. These mechanics’ cordless tools not only make the workflow smoother for car mechanics but also add the agility needed for effective automotive repairs and maintenance.

Essential Cordless Power Tools for Professional Mechanics

Professional mechanics and beginners in automotive work have distinct needs when it comes to cordless power tools. For professionals, high-torque cordless impact wrenches are essential for efficiently handling heavy-duty tasks like tire changes. Additionally, advanced diagnostic scanners with wireless capability become crucial for identifying and addressing complex electronic issues in modern vehicles. Professional mechanics may also invest in a comprehensive set of cordless tools for mechanics, including ratchets, drills, and grinders, all of which contribute to a seamless workflow and enhanced efficiency in a professional setting.

Cordless Power Tools for Beginner Mechanics

Beginners can start with more versatile and affordable cordless tools. A mid-range cordless impact wrench offers sufficient torque for most tasks without the high cost of professional-grade models. A basic cordless drill/driver provides the flexibility needed for a variety of drilling and fastening jobs, making it an ideal tool for those new to automotive work. As beginners develop their skills, they can gradually expand their toolkit with additional cordless tools such as ratchets and angle grinders.

Ronix

4 November 2020