- 10min

- 6335

- 0

The applied science of developing and customizing instruments to meet the physical demands or capabilities of the user is known as the Ergonomic Power Tool and hand tool business. This scientific subject also aims to mitigate and prevent health issues that are linked to or induced by a certain type of labor or tool. The goal of ergonomically designed power tools is to decrease physical stress and weariness in order to improve worker performance.

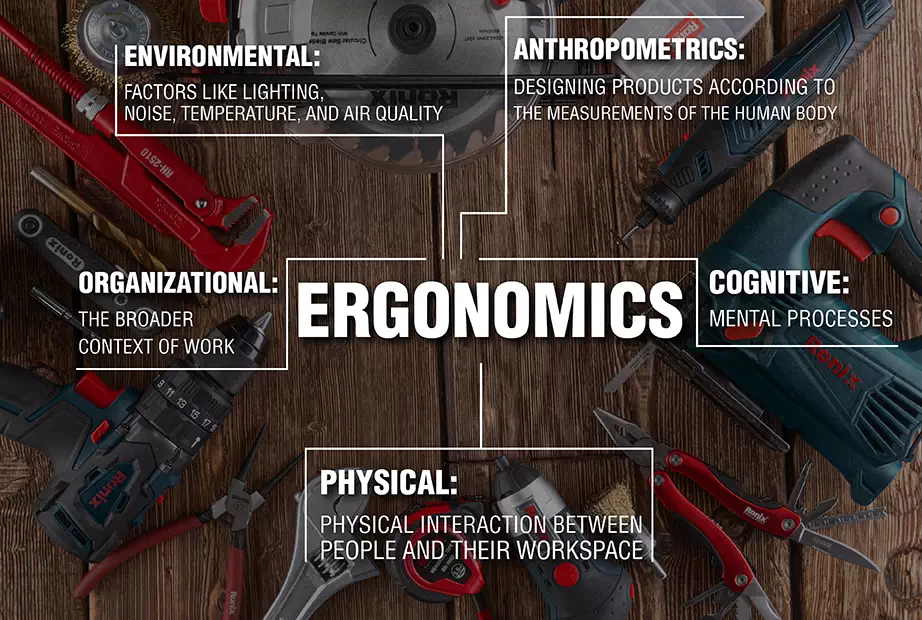

What Do We Mean by Ergonomics?

If we want to give you a general definition, ergonomics is the process of designing and arranging a working environment in a way that responds suitably to the limitations of humans. The goal of ergonomics is for humans to experience more comfort, safety, and efficiency. It has 5 key aspects:

- Physical ergonomics: physical interaction between people and their workspace

- Cognitive ergonomics: mental processes

- Organizational ergonomics: the broader context of work

- Environmental ergonomics: factors like lighting, noise, temperature, and air quality

- Anthropometrics: designing products according to the measurements of the human body

Determining the Meaning of Comfort

It’s typical to adjust the weight, balance, shape, and vibration of power tools to improve ergonomics and the less measurable problem of comfort.

Lighter-weight tools have been produced, thanks in part to the use of lighter housing materials. Because polyimides with fiberglass reinforcements are more robust and lighter than metal, they are becoming increasingly popular. Because of its durability and lightweight, tool specifiers are expected to see more magnesium tool housings. Nonetheless, improvements from modifications in house materials may have reached a nadir.

📌 Instead, many manufacturers are relying on technological advancements to make instruments lighter. Electronic clutches, which take up less space and are composed of lighter materials than mechanical clutches, may be used in newer machines.

That developments in fan design allow manufacturers to enhance tool horsepower without adding weight from a bigger motor or more copper windings – an improvement that is undoubtedly at the top of everyone’s wish list.

If you are interested in learning more about all the features of a drill, you can read the article Cordless Drill Features to Look for in a Tool, which is written exclusively in this regard.

What are ergonomic power tools?

In a nutshell, every ergonomic tool is designed in a way that fits human physic. As tools are supposed to be used for extended periods of time, they should be designed in a way that doesn’t strain the hand and the body. This issue becomes more significant when working with bigger tools that are powered and usually heavier than hand tools. Ergonomic power tools are as comfortable and safe as possible so that they can eventually increase workers’ productivity and well-being.

The Best Ergonomic Power Tools

We hope that up until now you’re kind of convinced that if you’re looking to buy a power tool, ergonomics is what you need to be keeping in mind.

But if you still need more information, we’re here to let you in on their benefits. The list below will also be your guide to buying the best ergonomic power tools.

Power Tool Triggers

Frequent index finger motions when working the trigger of power tools (such as a power drill) increase the risk of “trigger finger” and “trigger thumb” (tendonitis in the index finger and/or thumb). A longer trigger that can be activated with two or three fingers decreases pain and lessens the chance of harm.

Vibration

The only way to effectively eliminate vibration in power tools is to do it during the design phase. Because of this, tool selection is extremely important. “Anti-vibration” materials will suppress some vibrations above certain frequencies that are specific to the substance.

Ergonomic Handle for Power Tools

If you don’t want to strain your hands, you’ve got to pay attention to handles. You’re going to need to look for characteristics in a handle that help you figure out if the said tool is the best ergonomic power tool for you.

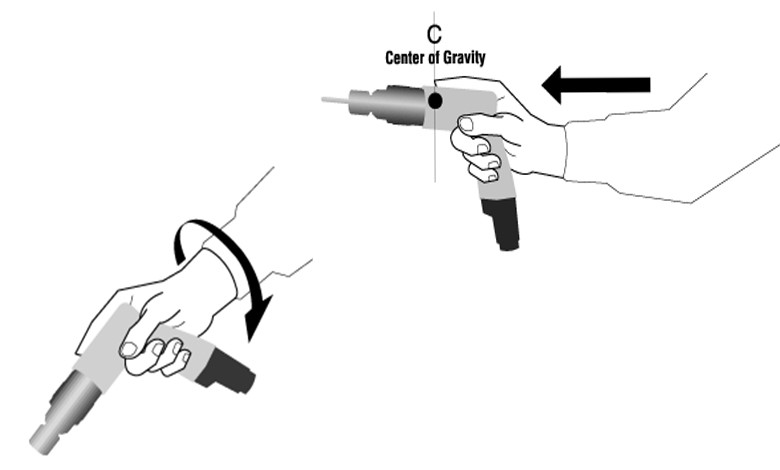

Handle Locations

When paying attention to power tools ergonomics you should consider if the handles are positioned to offer optimal balance. They should also allow for convenience, precision, and maximum control. For example, the handle of a drill must be comfortable while also providing support, control, and balance in order to ensure proper drilling and minimize drill bit breakage.

Handle Design

The shape, thickness, and texture of the handle are just as significant as its position when searching for ergonomic power tools. Manufacturers face a problem in creating power tools that can be handled comfortably by hands of diverse shapes and sizes in a variety of circumstances. It was formerly assumed that compressing a clay mold would provide the optimal handle shape. Apart from the fact that this design would only accommodate little hands, it also confines the user to a single constant posture, causing poor circulation and numbness.

Depending on the tool’s power, weight, and friction, an ergonomic power tool may have a long or short handle that is curved, straight, or contoured. The tool prevents concentrated pressure spots on the hand and allows the user to operate in a range of postures, including overhead drilling, squatting, and so on. The tool fits a variety of hand sizes, has no pinch spots, and reduces user fatigue.

The texture of the handle is another design feature. With or without gloves, the texture on the grip section of the handle provides an anti-slip surface. This rough surface also helps to keep the skin cool by enabling air to circulate between the tool and the hand.

User Posture and Performance Features

An ergonomically designed power tool’s primary goal is to allow the operator to perform an application while keeping a natural, comfortable position. It is the responsibility of the manufacturer to design power tools with functioning controls that are located in such a way that a suitable posture may be maintained.

The manufacturer prevents the user from having to look for a collet wrench or more drill bits by offering on-tool storage on other tools. This prevents the user from being able to maintain a comfortable work posture. Power tools with ergonomically built handles of a power tool allow the operator to apply the needed amount of pressure in a variety of hand positions, reducing fatigue.

Now let’s see what the characteristics of some ergonomic electric tools are.

Ergonomic Drills

Drills come in a variety of handle types, including T-style, D-style, spade, pistol grip, and combinations of these. Drilling “in line” with just one hand is possible because of the more compact pistol grip design. However, when bit sizes get larger and the material being drilled necessitates it, it is strongly suggested that you use two hands to operate the drill.

Ergonomic electric tools like drills should have the features below:

- Handle design: A grip that serves the shape of the hand and is made from grippy materials

- Vibration dampening: Not transferring the full vibration from the impact of drilling to hands

- Balanced weight distribution: Easy to control and manhandle by the user

- Variable speed and trigger control: Having options to change the speed and power according to the task

- User-friendly chuck: Easy opening and closing the bits

- Lightweight design: You need to be able to handle it for a long time, and easily

Everything about best power tools.

- LED work lights: For better vision when working, especially in dim areas

- Longer battery life and fast charging: Extra important in electric tools ergonomics

- Ergonomic accessories: Such as auxiliary handles, side handles, depth stops, …

- Quick release and bit holders: For easier switching between drill bits and driver bits

- Safety features: Such as electronic brakes

- Tool-free depth adjustment: For setting drilling or driving depth without any other tools

Ergonomic Chain Saw

On the subject of electric tools ergonomics, let’s also see what you should be looking for when choosing a chain saw.

- Handle design

- Anti-vibration

- Balanced weight distribution

- Lower weight

- Anti-kickback ability

- User-friendly control

- Noise muffling

- Automatic chain lubrication

- Adjustable handles

- Quick release

- Safety options

- Ergonomic accessories

- Easy maintenance

Ergonomic Electric Screwdriver

In an electric screwdriver as a power tool, ergonomics matter because there are a lot of screws to be driven in a project! So, what needs to be kept in mind when choosing one?

- Handle design and material

- Vibration lessening

- Balanced weight throughout the device

- Lower weight

- Variable speed and trigger control

- Easy-to-use chuck

- LED lights

- Battery longevity and fast charging

- Ergonomic accessories

- Quick release bit holders

- Safety options

- Tool-free depth adjustment

Conclusion

While a manufacturer may claim that its power tools are ergonomically designed, the user is the final arbiter. Pick up a tool before you buy it based on its performance features. If the tool doesn’t feel at ease at the store, it won’t feel much better when it’s put to use.

FAQs:

What do you mean by ergonomics?

Designing, arranging and planning for work environments to be safe, comfortable, efficient and in short, corresponding to humans and their specificities.

What are ergonomic tools generally?

Tools that prioritize user’s safety, comfort and efficiency and doesn’t strain the user’s hands when in use for long periods of time.

How could power tools be ergonomic?

With having a comfortable handle design with a good grip, anti-vibration design, balanced weight distribution, speed options, easy adjustments, reduced noise, dust collection, lighting, ergonomic accessories, ….

What are some of the ways that power tools might cause ergonomic injuries?

Vibrations from tools that are too strong can reduce blood flow, injure nerves, and induce muscular weariness.

What is an Ergonomic Power Tool grip?

To enhance product design and/or employee performance, identify and study the stresses and pressures felt by each finger, thumb, and palm.

What are the benefits of Ergonomic Power Tool tools?

Ergonomics is crucial since your musculoskeletal system is influenced while you’re working and your body is strained by an inconvenient position, severe temperature, or repeated movement.

Ronix

12 December 2021