- 16min

- 15680

- 0

From Space to Your Home: A Trip to Find the Best Welder

In 2022 streets of California witnessed blue trucks with pictures of astronauts and spacecraft featuring a big NASA logo. But these vehicles had little to do with what everybody usually expects. They were carrying neither space radar equipment, nor robots, and definitely not ALIENS’ DNA SAMPLE!

Unbelievably, they were just on-wheel fabrication shops that were built to show the importance of Welding in NASA developing their goals…

Are you looking for a professional welding machine supplier to support your business?

This industry is tailored to every single aspect of our lives, from home uses to the most complicated technological applications. That’s why finding the Best Welding Machine for each job should be a priority for every handy person who is into fusing metals to make them a part of their life and profession.

For the first step, let’s get into three popular types: MIG, TIG, and Stick Welders, and see what features make them the best!

A Brief Look at the Features of Best MIG Welders

MIG (Metal Inert Gas) welding machines work like this:

They use a wire electrode that is fed through a welding gun and into the weld pool. The wire melts and fuses the two metal pieces together. Regarding their function, for finding the ideal MIG welder look for the following traits:

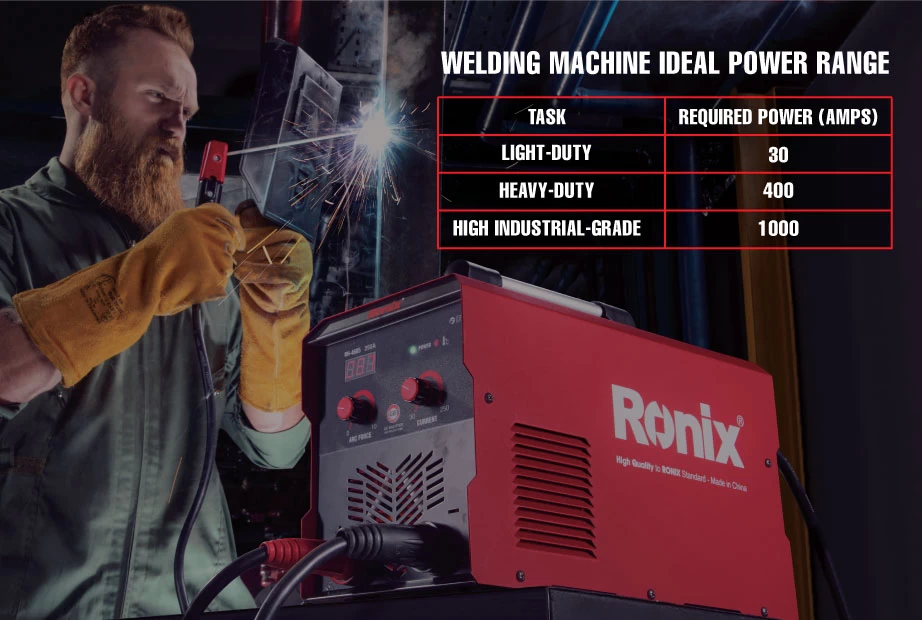

Amperage Range

Look for a MIG welder with an amperage range that can handle the thickness of the materials you will be welding. A wider amperage range allows for more versatility in welding different types of materials. The sufficient span would be from

30 Amps for light-duty tasks such as welding thin sheet metal or light gauge steel

to

400 Amps for heavy-duty jobs such as welding large structures and components for heavy machinery.

However, MIG can perform even 1000 Amps which suits industrial-grade activities. Right, rarely used, but possible!

Wire Feed Speed Control

The control over the speed of the electrode wire when is fed out of the gun is an important factor. The ability to adjust the wire feed allows better control over the weld and ensures a stable arc.

Overload Protection

A MIG welder with overload protection will shut off automatically if it becomes too hot or overloaded, preventing damage to the machine and ensuring safety.

Gas Regulator

A good quality gas regulator ensures consistent gas flow, which is essential for creating high-quality welds.

Spool Gun Compatibility

If you plan to weld aluminum or other non-ferrous metals, look for a MIG welder that is compatible with a spool gun for better control over the welding process.

What Is Special about the Best TIG Welding Machines?

TIG (Tungsten Inert Gas) welders’ function is as follows:

They use a tungsten electrode that is used to heat the metal pieces to be joined. A filler rod is then added to the weld pool to create the joint. Here are some of the specific features they should deliver for an ideal performance:

A Wide Ampere Range

A good TIG welding machine should have an amperage range that can handle the thickness of the materials you will be welding.

This type typically requires a lower amperage range than the MIG, because it should be more precise and work with thinner metals and do delicate welds. Regarding all the functions, the amperage can vary based on the applications and types of metal it uses, but generally, it can be from around

5 Amps for very thin applications such as welding jewelry, electronic components, and dental work such as welding braces and retainers

To

300 Amps for thick metals, structural steel, aerospace components, and power plants.

AC/DC Capability

If you plan to weld aluminum or other non-ferrous metals, look for a TIG welding machine that has AC/DC capability. AC/DC machines (Ronix RH-4603) allow you to switch between AC (for aluminum) and DC (for steel and other metals) welding.

Our Recommendation:

DC Arc Welding Inverter 200A Ronix RH-4693

DC Arc Welding Inverter 200A-Turbo fan plus Ronix RH-4604

DC Arc Welding machine 20 200A Ronix RH-4607K

Foot Pedal Control

A foot pedal allows for better control over the welding process and is more comfortable than using a hand-held control.

High-Frequency Start

A high-frequency start allows for easy and reliable arc starting, which is important for creating high-quality welds.

Pulse Control

Pulse control allows for better control over the heat input and can help prevent warping or distortion of the metal being welded.

Water Cooling

If you plan to weld for extended periods of time, a TIG welding machine with a water-cooled system can help prevent overheating and extend its life.

Like MIG ones, when seeking a professional welding machine consider the portability and duty cycle of the TIG welder and its digital display as well.

What Do the Best Stick Welders Offer?

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a type of welding process that uses an electrode (or “stick”) consisting of a metal core coated in a flux material. The electrode is inserted into a welding machine, which provides an electric current that melts the electrode and the base metal, fusing them together to form a joint.

Stick welding is a popular welding process because it is versatile and can be used to weld a variety of metals and thicknesses. It is also relatively simple and inexpensive compared to other welding processes.

When selecting a stick welder, there are several features that are important to consider to ensure that you get the best machine for your needs. Here are some of the key features to look for in a stick welder:

Arc Stability

A stick welder with good arc stability will produce consistent welds with minimal spatter and slag.

Adjustable Arc Force Control

This feature allows for better control over the welding arc, especially when welding thicker materials.

Hot Start and Anti-Stick Features

This help to prevent the electrode from sticking to the workpiece and ensure consistent starts.

Overload Protection

Like the other types, this turns the unit off in case of excessive heating, to protect the machine from harm.

Input Power Voltage

Ensure that the stick welder is compatible with the voltage in your work area to prevent damage to the machine.

Take all the points above into consideration, when looking for a professional stick welder, but don’t overlook features such as Amperage range and weight as major factors.

Best Welding Machine for Aluminum

Be it under seas or up high in the clouds, Aluminum finds its way to being an inseparable part of technological equipment. It is corrosion-resistant, so perfect for marine and submarine structures; lightweight, so ideal for aerospace industries. But this is not the end of the story: construction, automotive, and electrical industries are just some of the fields developed with the help of this versatile alloy.

Then you may figure out how important its fabricating can be!

While you can fuse this lightweight alloy with different types of welding machines, many experts believe that TIG welders are the best welding machines for Aluminum.

Because the melting point of aluminum is so low, excessive heat can cause distortion in this alloy. While TIG, with its controlled heat input, can take care of it perfectly and cause the least twist and damage. Besides, TIG can be used for a variety of aluminum alloys, including those with high magnesium content, which can be difficult to weld with other machines.

The Lincoln Electric Square Wave 200 TIG Welder is one of the top rated welding machines. It’s a great choice for crafters, fabricators, and hobbyists. Weighing about 46 pounds, it’s easy to carry and simple to use, making it very popular. This welder lets you adjust the AC frequency, which helps control the weld bead and results in smooth, clean welds, especially on aluminum.

Best Welding Machine for Cars

Anybody who is in the automotive industry may have heard of welding schools and colleges at least one time in their professional life, Northern College, and Institute de Soudure are some of them. Welding is so crucial in this field that many leading car companies such as BMW, Ford, Porsche, and Mercedes Benz set courses for educating pro-welders for their production lines. That’s why everyone in this area should find the best welder for working with cars.

When it comes to welding machines for the automotive industry, there are several features to consider to ensure that you choose the best one for your needs.

First, you can use various types of professional welding machines, including MIG, for welding metals such as steel and stainless steel, TIG for automotive body repair, and RSW for welding high-strength steel, used in modern vehicles for improved crash safety.

Each of these tools needs to deliver specific powers to be efficient in the industry. For example, the MIG with 150 to 250 amperage can be a great fit, while for TIG at least 250 amps would be perfect.

More than this, the best welders for cars, no matter what type, should be durable, easy to use, portable, and equipped with built-in safety features such as thermal overload protection, voltage and amperage protection, and automatic shut-off in case of a malfunction.

One model that has received positive reviews from professional welders is the Vulcan MIGMax 215. This welder is also beginner-friendly, with a user-friendly design that makes it easy to operate. It features dual voltage input (120V/240V) with an auto-sense function, providing the flexibility to weld in various environments. Users have consistently praised the MIGMax 215 for its ease of use and reliable performance. The settings are simple to adjust, and the ability to work with different wire sizes is highly valued. so If you have a car to work on, this model is a good choice to consider.

The Best Welding Machine for Beginners

All of us have worked as a beginner someday. Then you can remember how complicated the tools seemed to be. Clearly, when you are a newcomer to a field, you need to use a tool that has a simple structure and is easy to use. But what are the exact features?

MIG, TIG, or Stick Welders?

Let’s omit the option which is less suitable for beginners first: TIG welders are so advanced, and require higher levels of skill and experience. So, we can put them aside for two other types which seem more compatible with a beginner’s needs.

On the other side, MIG welding machines are considered to be incredibly user-friendly and easy to learn. They are highly versatile and easily set up. While stick welding machines are so simple too. Besides, it is affordable and can be used for different types of metals.

So, both MIG and Stick can be good matches for beginners, so if you are a beginner, see what are your preferences and needs, then choose between them.

Check out our article on ‘4 Steps to Choosing the Best Welder for Beginners’

Ease of use

Look for a welding machine that is easy to set up, use, and maintain. Don’t rush to buy a complicated one that needs a hefty manual to figure it out!

Instead, a simple and intuitive interface, clear instructions, and easy-to-access controls can help make the welding process smoother for you as a beginner.

If you’re searching for top welding machine brands to kick off your projects, there are plenty to choose from. My personal favorite for beginners is the Hobart Handler 140 MIG Welder

It’s a favorite because it’s simple to use, affordable, and works really well.

The Handler 140 can weld up to 1/4 inch thick in one pass and has an amperage range of 25 to 140, making it versatile for lots of different jobs. Plus, the 5-position voltage control makes it easy to adjust for whatever you’re working on.

Whether you’re fixing up a car or working on more detailed projects, the Hobart Handler 140 is a solid choice to get started.

Best Welding Machine for Home Use

Working at your own place can be as exciting as an adventurous journey! You will find every single potential of being creative right where you spend your everyday life. But like any other new exploration, it can turn into a real disaster if you don’t mind safety! Specifically when you are to face a great deal of heat, electricity, and a shower of sparks!

Due to the risks of this job, when you are welding you need to care more about your safety. And when you are doing it at home you should duplicate the protection. So, in case you want to choose the best welder for use at home, you should consider the safety features such as protection from over-voltage, heat, current, and overload.

However, ease of use should be another priority that you should not forget. That’s why using MIG or Stick welders is recommended if you are in DIY projects or non-professional uses. Of course, if you are a pro-user just working on their own at a home workshop, you can rely on TIG as well.

Obviously, when choosing, you should consider all the traits of the mentioned types of welding machines.

A welder that many people like is the ESAB Rebel EMP 215ic Stick Welder. It’s packed with advanced features and works with both 120V and 230V power, making it very flexible. Designed with help from professional welders, it’s an all-in-one machine that can handle MIG, MAG, DC TIG, and Stick welding on materials like mild steel, aluminum, and stainless steel. It’s also easy to move around. Weighing only 40 pounds, with a compact design and built-in handles, it’s perfect for taking to different job sites or moving around your workshop. A great option for home projects or portable welding needs!

Best Welder for Pipeline

They are usually hidden beneath the walls, ceilings, and floors, unseen but highly important in every construction. Fabricating them properly is crucial as well. So, you need to put finding the best welder for it first.

The type of welder that should be used for pipelines depends on several factors, including the welding process, the material, and the applications. As other fields talked about, stick welders (good for steel pipes), TIG (for stainless steel, aluminum, and non-ferrous metals), and MIG (for thin-wall pipes) are great options. But there are still more types that can help in fusing pipelines together:

Flux-Cored Arc Welding (FCAW)

This welding process is commonly used for welding pipelines in outdoor or windy environments where gas shielding may be difficult.

Submerged Arc Welding (SAW)

This type is commonly used for welding thick-walled pipes and can produce high-quality welds with minimal spatter and distortion.

The Ronix RH-4603 is a fantastic pick for pipeline and one of the best options out there. It’s a DC arc welding inverter that offers up to 180 amps of power and runs at 7.6 kV.

DC arc welding inverters are portable tools that turn electrical power into direct current (DC), which is perfect for welding. They’re known for being efficient, easy to carry, and great at creating steady welding arcs. You’ll find them handy for all sorts of jobs, like repairs, construction, manufacturing, and even automotive work.

Best Overall Welding Machine

Choosing the best welding machine can be tricky because there’s no one-size-fits-all solution for every person or project. However, when it comes to the top welding machine brands on the market, my pick today is Miller Electric.

Miller Electric is a leading manufacturer of welding machines and equipment. They are known for their high-quality products, reliability, and innovation. Miller offers professional welding machines for various applications, such as MIG, TIG, Stick, and plasma cutting.

The Miller Multimatic 215 is Miller’s latest portable welder and one of the most popular welding machines, designed to make your welding projects easier. With the ability to do MIG, TIG, and stick welding, it’s super versatile and packed with power—perfect for all kinds of light industrial work. This standard package (for MIG and stick welding) includes everything you need to get started: the main unit, a wire feeder, and a MIG gun.

Best Welder for The Money

Money matters in the professional welders’ market too. Along with all the concerns, users of all the fields will consider the prices of the equipment as a leading factor. Yes, they may buy first-rate welders that are pricy, but definitely, they will prefer high quality at affordable prices.

There are not many brands in the market that attempt to bridge the gap, but that doesn’t mean that No Brand will do so. Ronix is one of the brands with the ultimate goal of filling the space between greatness in function and being fair in prices.

You can find a wide span of professional welding machines in the Ronix collection that can tackle your fabrication tasks in any field and industry.

My top choice is the Ronix RH-4693. It supports electrodes from 1.6 to 5.0 mm, making it ideal for everything from automotive repairs and small-scale fabrication to DIY projects and professional maintenance. The anti-stick and hot start features are perfect for beginners, while the digital display, precise control knobs, and multi-protection systems eliminate concerns about overheating and overload.

Read More : 60 Welding Machine Manufacturers

FAQ❓

What kind of welders do professionals use?

If you want to choose among the three popular types: MIG, TIG, and Stick welders, the most professional one is the TIG version, which is more precise, but not as easy as the two others to work with.

Is stick welding stronger than MIG?

Both stick welding and MIG can produce strong welds, but the choice between the two depends on the specific requirements of the welding project.

Amanda

31 July 2023