- 6min

- 13052

- 0

Ronix, the emerging international tool brand, has recently launched a powerful new lineup of all-in-one 40V cordless tools. In this article, we’ll break down everything you need to know about 40V vs 20V, from power output and performance to durability, runtime and use cases, to help you decide whether upgrading to the new 40V ecosystem is the right move.

Here’s the short and easy answer: If 20V tools are getting the job done for you, there’s no need to change anything! Why fix what ain’t broke, right?! (I’ll even explain why the runtime difference isn’t as big as you might think.) But if you do your work wondering from time to time whether there’s a more powerful and more efficient way to work, this article is for you!

What Does 20V vs. 40V Technically Mean?

To understand the real difference between 20V vs 40V cordless tools, we need to look beyond marketing labels and into the battery architecture itself; this might get a little technical; so, feel free to skip ahead if that’s not your thing!

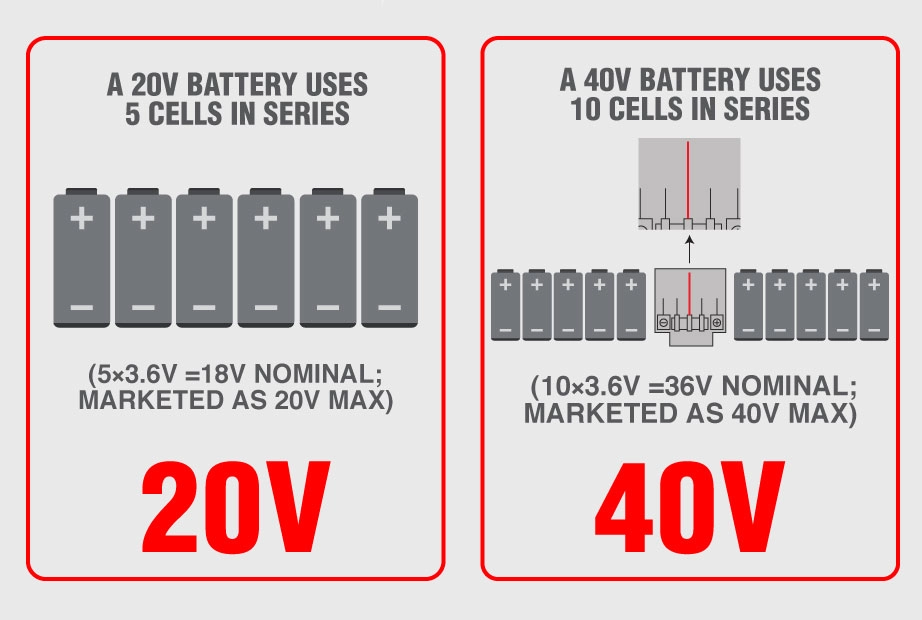

Both voltages use lithium-ion cells, that is the same cylindrical batteries found in everything from laptops to electric cars. Each cell has a nominal voltage of 3.6V, and tool batteries are built by connecting multiple cells in series.

So, how does 20V vs 40V actually work?

- A typical 20V battery is made up of 5 cells in series (5 × 3.6V = 18V nominal; marketed as 20V max).

- A 40V battery uses 10 cells in series, giving you 36V nominal, marketed as 40V max.

So, while the “20” and “40” labels refer to maximum output straight off the charger, the actual working voltage is slightly lower, but the difference is real! With double the number of cells, 40V batteries can deliver significantly more sustained power!

This matters most when you’re using tools that draw a lot of current, like rotary hammers, chainsaws or impact wrenches. Higher voltage means less current is needed to generate the same (or greater) output, which results in less heat, less wear and better overall efficiency.

If you’re choosing between platforms, this is the starting point: 40V is built to do more with less strain! Simply put, the Ronix 89 Series 40V tools not only easily outperform 20V cordless gear but also challenge the power of corded tools: without the cord!

Power and Performance

When it comes to cordless tools, voltage isn’t just a number on a label: it directly affects how much raw power your tool can deliver. In the 40V vs 20V debate, both batteries use similar lithium-ion cells, as mentioned before, but the 40V platform doubles the number of cells, which lets it deliver more consistent energy to the motor.

This is most important to take into account in high-demand applications. Think about the moment you fire up a chainsaw, or bore through dense concrete with a rotary hammer! In these conditions, higher torque is always a good enhancement, right?! That’s where the 40V battery system comes to play!

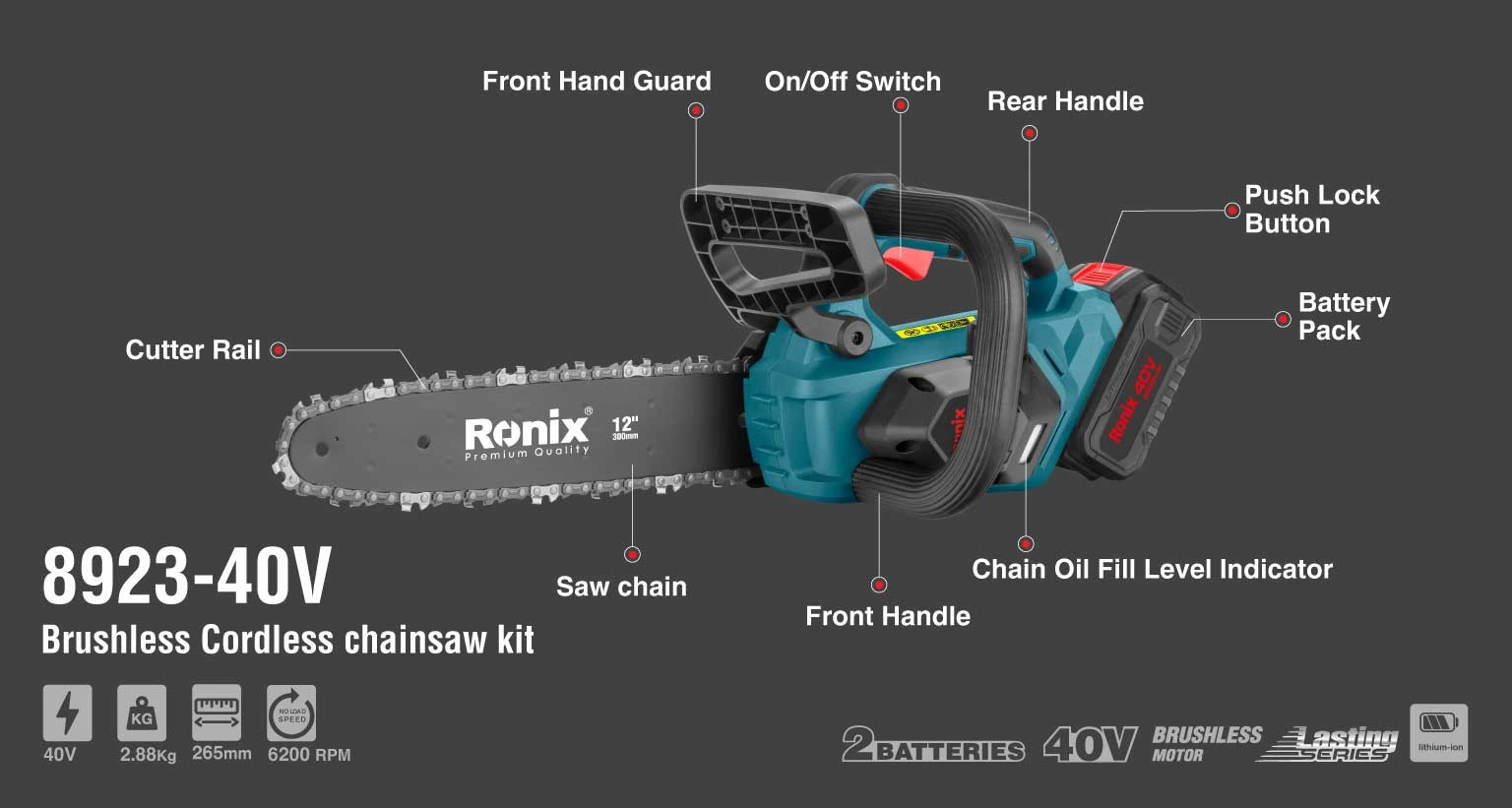

For example, take the Ronix 8923-40V Chainsaw Kit : a 30cm bar and chain topped with the 40V battery! When you look at the specs alongside its real-world performance, you know it’s not just for some casual DIY tasks around the workshop. It’s been made for much more than that. Like the kind of rugged environments found in super heavy industrial use!

Similarly, the Ronix 8910-40V Rotary Hammer Kit with 2.4J impact energy and 28mm drilling capacity brings the kind of punch you’d expect from a corded tool, but with all the cordless freedom! This is where you really start to see the difference in 20-volt vs 40-volt performance!

Durability and Runtime

When it comes to durability, technically, a larger battery technically suggests longer runtime. However, in real-world use cases — especially when performance is prioritized — runtime doesn’t always increase in 20-volt vs 40-volt power tools. Instead, the extra power is used to deliver stronger output, not necessarily extended operation.

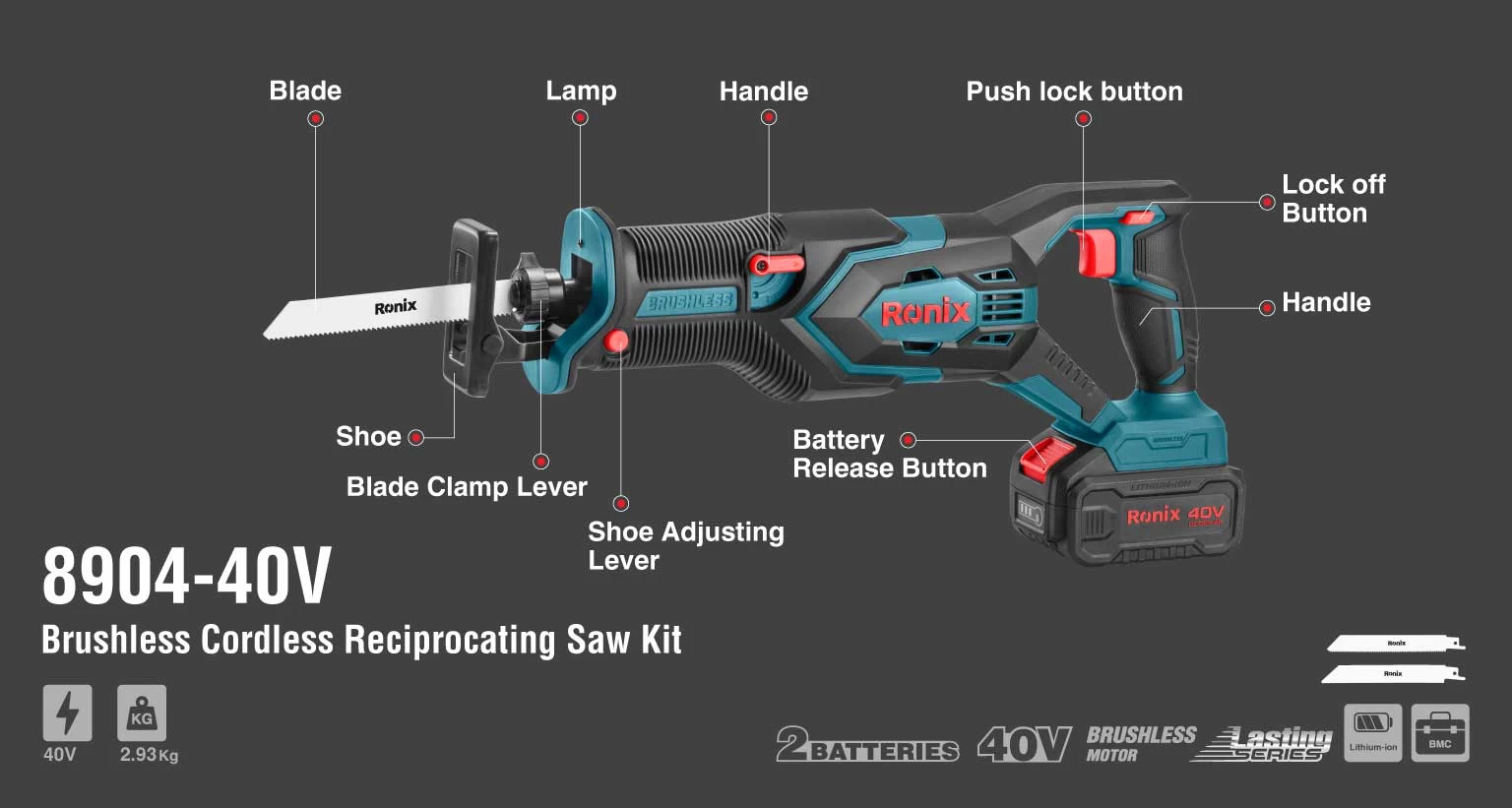

Take the Ronix 8904-40V Reciprocating Saw Kit, for example. This is not your average reciprocating saw. It draws from the 40V source and delivers performance on par with corded models. It cuts through everything from simple wood to tough metal without putting stress on the motor or battery.

That said, in similar work conditions, you won’t always see significantly longer runtime compared to a 20V tool. What you’ll notice is more power, not more minutes. And that’s the real difference when it comes to 40V vs 20V in power tools.

Why 40V Is Ideal for Pros

To put it simply, 20V tools are a great choice for users who don’t need the power of corded tools but want the freedom of cordless ones. But when professionals step in, that’s where 40V tools truly shine! They’re built for those who can’t deal with the hassle of cords — yet need more power than what a 20V system can deliver. That’s exactly where Ronix’s all-in-one 40V lineup comes in! The series is built to keep things moving as efficiently as possible, even under intense pressure. As Mr. HR Ramkhoo, Supply Chain Manager at Ronix Tools, puts it:

“These tools are not designed for casual or occasional users. The target audience for this lineup is ultra-heavy-duty professionals: individuals and teams working long hours on high-pressure industrial sites, including welding and metalworking shops, road and structural construction projects and heavy fabrication environments. These are places where tools can’t afford to slow down, and the Ronix 89-series 40V lineup was built for exactly that level of performance.”

Which One Should You Choose?

So, if you’re a casual user, DIYer or just need a lightweight tool for lighter projects, 20V tools still have a place. They’re compact, easier to handle and are generally more affordable. But if you’re in it for performance, run large tools or simply want a future-proof system that handles serious work: the 40V platform is the smart investment! Especially when it comes with the durability and design of Ronix’s new all-in-one 40V series.

Conclusion

The bottom line is: compared to 20V tools, 40V tools aren’t just more powerful, they’re built to be all the more stable under heavy loads of industrial pressure. Whether you’re cutting, drilling or grinding, the higher voltage keeps your performance sharp and makes every job done faster and easier.

Nika

11 May 2025