- 13min

- 3329

- 0

Anyone who has ever been to a construction site, on an oil rig, or just using tools for their DIY projects has understood just how dangerous tools can be. From flying shards to accidental bounces, accidents are not that rare in worksites, and it has caused countless physical damages to people. PPE was invented with the intention of minimizing the exposure to these damages, whether they are chemical, electrical, physical, etc. They have been so effective in saving people that they’ve become mandatory on construction sites and a lot of other places, so what do you need to protect yourself in this dangerous mechanical world?

Find an Ideal Wholesale Safety Equipment Supplier to fill in your inventory with premium tools

What Does PPE Mean?

Personal Protective Equipment is an essential safeguard, the last line of defense when engineering controls fail or being careful isn’t enough to eliminate the risk. According to OSHA (Occupational Safety and Health Administration), PPE prevents millions of serious workplace injuries each year in the United States alone. Its importance cannot be overstated, it saves lives.

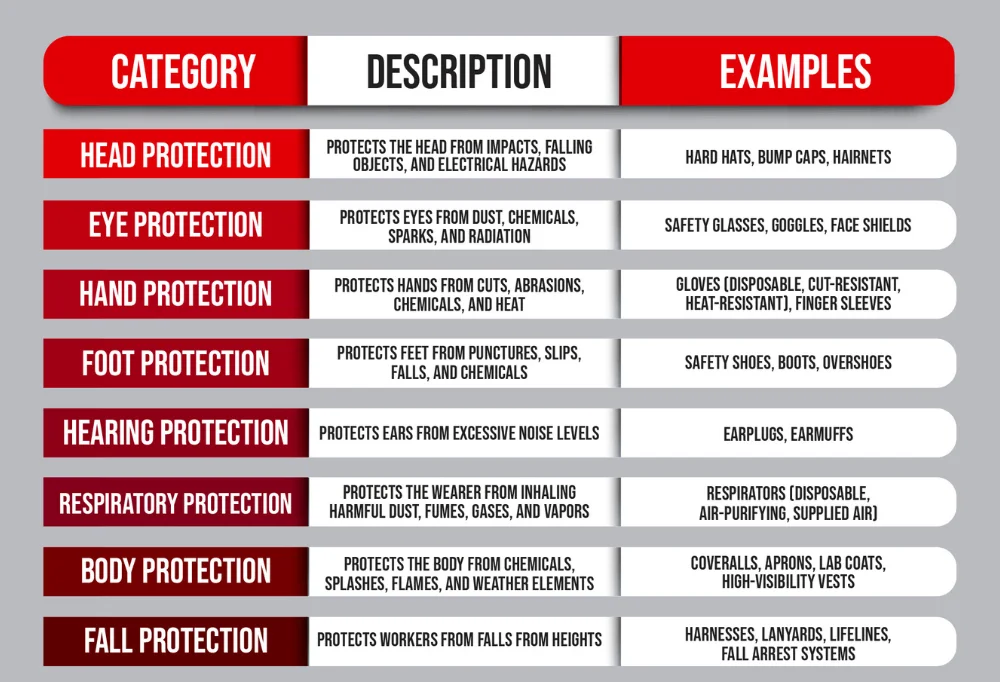

Types of PPE

There are different types of PPE you can use based on your work and needs. Sometimes a simple glove is enough to stay safe from danger, and sometimes you need a full body suit to not get splashed with chemicals! Here’s the top PPE list:

Head Protection

Hard hats have been the most common sort of protection for decades now. They are necessary for environments with the risk of falling objects, places like construction sites and mining operations. Hard hats are made from fiberglass or high-density polyethylene. It’s somewhat obvious that they work by absorbing the impact and protecting the head (the most important part of the body, so we are very thankful for hard hats). There are also specific types that match different needs, like bump caps for low-level bumps, or electrical-insulated hats for working with electrical dangers.

The Ronix RH-9092 is a great choice for your safety helmet. It’s made of ABS which is impact-resistant, it’s also ultra-light to make those heavy working days a bit easier on your head and neck. This helmet also has replaceable soft brow pads and a low center of gravity for great balance. The suspension bends make them a good fit for any size, so you wouldn’t need to worry about the size of your head!

Our Seggestion:

Ronix RH-9090 Safety Helmet-Yellow-PE

Ronix RH-9092 Safety Helmet-White-ABS

Eye Protection

The most typical example of eye protection in dangerous situations is safety glasses. They shield your eyes from flying debris, broken shards of an angle grinder’s wheel (believe it or not, there are photos on the internet of safety glasses stopping those), or just simply dust. Safety glasses also have different types, like polycarbonate lenses that are impact-resistant and used generally. Then we have welding helmets (which make you look like a cool Star Wars character by the way) that have special filters for light and radiation protection in the welding process. You can also use goggles with chemical-resistant coatings to protect you against rogue splashes.

The Ronix RH-9027 Welding Safety Glasses should be your choice if you are looking for something to protect your precious eyes. They have integrated headbands that are both wide and adjustable so they fit your face properly, and they’re made of Polycarbonate frames which are very impact-resistant. The clear shields provide a wide-angle view and the padded temples/ nose bridge helps with comfort. These glasses are designed to work in high temperatures too, up to 80 degrees! The lenses have anti-fog, wind, and sand coatings too. The Ronix RH-9027 is designed specifically for welding and metal-working, so use it to its full potential.

Hand Protection

The type of glove you pick depends on the specific hazard you’re dealing with. Heat-resistant gloves are for handling hot things, like metal-working or glassblowing. Cut-resistant gloves that are made from Kevlar help with protection against cuts or lacerations (God knows how many fingers these have saved), and chemical-resistant gloves usually made from nitrile or butyl rubber will save you from dangerous liquids.

Keep in mind, you need to choose the right one, because choosing the wrong type of glove may at best be ineffective and at worst add to the danger you are facing.

If you’re looking to protect your hands after reading this, you need to take a look at The Ronix RH-9010. These safety gloves have a special nitrile coating on the pal, and finger parts of the glove. They are abrasion-resistant, durable, highly elastic and allergen-free. They come in a variety of sizes for the comfort of your hand as well!

Foot Protection

Safety shoes and boots protect your feet against punctures, falling objects, electrical currents and hazards, or spills. The most famous and common type of these boots is steel toe boots which are great at saving your toes (appropriately named shoes as you can see) from impact or crushing injuries. There are also metatarsal guard boots that offer some extra protection against these dangers.

Hearing Protection

Both earplugs and earmuffs are our ear-saving PPEs that protect you from loud noises that may be louder than the safe exposure limits. They prevent tinnitus and noise-induced hearing loss. Choosing one or the other depends on the job you want it for, and the Noise Reduction Rating (NRR). Earmuffs get the job done in most situations but they are awfully uncomfortable in humid and hot environments. Earplugs on the other hand are smaller and easier to carry but they may be a hard fit and they’re kind of easy to lose.

Respiratory Protection

Respirators provide the breathable air when you need it the most. They’re for working with harmful dust, fumes, vapors, gasses, or any other airborne contaminants in your workplace. Again, the type you pick depends on your needs. There are two main types of respirators:

- APRs (Air-Purifying Respirators): The simpler type that uses a filter cartridge to clean the air before it gets to you.

- SARs (Supplied-Air Respirators): The more advanced type which provides clean breathing air from a hose and an air cylinder on the back of the worker.

Body Protection

Everyone thinks of body vests when they think of PPE, those bright green/orange vests that are ever-present in every construction site. So what is body protection exactly used for?

- Vests: They’re protection for the torso, and are worn over clothes. Vests are used when full-body protection is not necessary. Vests give you some splash protection, and they’re a bit of a barrier against dirt, dust, and debris. The fact that they’re made from high-visibility material makes them necessary for working in low-light conditions or environments where there are moving vehicles. OSHA has a rather dark fact on their site: “One in four “struck by vehicle” deaths involve construction workers, more than any other occupation.”, which makes it very clear why a high-visibility vest is an absolute necessity.

- Full-Body Suits: This is the most thorough protection there is. Full-body suits cover the entire body from head to toe and they belong in highly dangerous environments. In places where there is significant exposure to harmful liquids, working in pressurized atmospheres, or where there is a biological risk, these suits are lifesavers. They can also use the SARs we mentioned before, to supply breathable air.

Fall Protection

Falling, the leading cause of death in construction. Over a third of construction deaths are the results of falls, and there has been a great amount of effort to stop these tragedies. How, you ask?

- Harnesses: Full-body harnesses spread the fall force across the body to reduce the risk of injuries like suspension trauma. They have different levels of comfort, mobility, and weight capacity which you need to consider when choosing one.

- Lanyards: These connect the harness to a secure anchor point. Because of their different lengths and materials, they should be chosen based on the Maximum Arresting Force (M.A.F) that may be needed. Shock-absorbing lanyards or “lifelines” absorb the impact forces of a fall, and that reduces the peak force that is transmitted to the worker, saving them from a broken back or neck.

- Anchorages: These are the secure points that were mentioned before. They can tolerate the falling forces, can be temporary or permanent, and the selection depends on factors like the weight of the worker the potential fall distance, and the specific work environment.

Even after you’ve gotten to know all these PPE categories, the job is not done yet. You still need to choose the right PPE for the task at hand. You need to choose one that fits well since ill-fitting PPE can either be ineffective or dangerous. You also need to inspect PPE for damages or wear and tear and replace the damaged or worn-out equipment as soon as possible, since this is not something you can risk on. Some PPE needs cleaning and filter changes after every use. And at last, train the workers on how to use and care for their PPE, as they can be pretty expensive!

The Uses of PPE

Now that we’ve gotten familiar with different types of PPE, it’s time to know where they are used:

Construction Sites:

These places without PPE for be terrifying, and that’s why it was most of what we talked about previously. They face a lot of danger on a daily basis, and PPE is their frontline defense.

Manufacturing:

Touching chemicals, breathing in dust, and hearing loud noises are constant threats. PPE saves these workers from burns, lung diseases, and hearing damage. Safety glasses and gloves are common in factories to protect against these risks.

Healthcare:

Everyone remembers how much more important PPE became in the times of COVID-19. PPE saved and continues to save healthcare workers from infectious diseases. They practically go to war every day to save lives, and their armor is the gowns, masks, and face shields against pathogens and body fluids. PPE prevents doctors, nurses, and other staff from getting spreading illnesses during patient care.

Emergency Responses:

Firefighters and paramedics face unpredictable dangers every day to save lives. Firefighters use heat-resistant clothing and respirators to run into the heart of the fire, and paramedics wear gloves and safety glasses to deal with injuries/potential biohazards.

Energy and Mining:

Miners wear hard hats, safety boots, and sometimes even respirators to shield them from falling rocks, breathing dust, or a potential explosion. In the energy sector, brave workers handle high-voltage electricity daily. They need special electrical-rated hazard gloves and boots.

Every industry has its own risks, and PPE is there to reduce those risks as much as possible. It’s not about following the rules, it’s about the wellbeing of the workers.

How Do You Determine the Best PPE for the Job?

All the factors that we’ve had until now can help you choose the PPE you need for your specific job, but it’s still a multi-step process:

What Hazard Are You Dealing With?

The assessment is the first step, to figure out the potential dangers that may threaten your safety or the safety of your workers.

Are You Breaking The Rules?

As you probably already know, different industries and jobs may have certain PPE requirements that you need to follow. Organizations like OSHA keep you safe by setting safety worker laws, you need to study them in order to make sure you’re in the green zone when it comes to the rules.

HOW DANGEROUS are we talking?

Not all dangers are created equal! You need to assess the severity of any potential injury or illness you may have to deal with. For example, working with some really harmful chemicals requires heavy-duty chemical-resistant gloves, but standard rubber gloves are enough for mild detergents.

Does It Fit and Is It Comfortable?

PPE needs to be comfortable because they are going to be worn for long periods. Who wants to work on a hot sunny day in an uncomfortable vest?

They also need to fit well. It is pretty self-evident why: if the respirators don’t fit properly, they’re not going to give you the seal you need, or bulky gloves are not flexible enough so you may have a problem handling stuff with them. So there needs to be a balance of protection and comfort.

Sometimes, It’s Too Specific

The type of the task may affect what PPE you need. You would be fine with light-weight gloves for laying bricks, but that’s not going to work for heavy-duty welding. So pay attention to what your task is going to be.

How Can Employees Verify the Functionality of a Workplace PPE Program?

There are certain things you can look for to make sure your employee has a good PPE program set up:

- Once More, Is There a Documented Hazard Assessment?

Does your workplace have any documents that show if they have assessed the dangers you may face? If yes, that’s a pretty good place to start.

- Do You Have Everything You Need?

Is appropriate PPE available? You cannot compromise on safety equipment, so if there’s a danger you are worried about, you need something to save you from it.

- Are You Properly Trained?

Knowing what PPE you need to pick up, knowing how to use them, and lastly, knowing how to maintain them can be the difference between life and death.

- It Doesn’t End There…

If all the previous boxes are checked, great! But that is not where the employer’s duty towards the employees’ safety ends. You still need regular inspections; you need to check the equipment for damages as said before.

What Source Provides the Best Information on PPE Requirements?

If we are talking about laws and regulations, it differs from country to country. However, the US Department of Labor has established The Occupational Safety and Health Administration (OSHA), a government agency with the main goal of keeping workers safe. Their regulations are the legal requirements for PPE use across The United States. OSHA offers advice on things such as gloves or safety glasses and even full-body suits, and they provide a lot of free resources and information on their website. It even has a training guide for employers on how to set up a PPE program!

And Lastly, Don’t Gamble on Safety!

PPE has become the armor against everyday hazards from construction sites to hospitals. Invest in your and your workers’ safety, don’t wait for an accident to happen, use all the tips and advice in this article to set up a PPE program. We wish you all a happy and productive work environment!

FAQs

What Type of PPE Clothing is Best for Hazards That Can Occur from Any Direction?

Full-body suits offer the most protection from hazards that can occur from any direction.

Which Type of Eye and Face PPE Protects Best Against Splashes?

For optimal protection against splashes, choose a full-face shield combined with safety glasses. This combination guards both the eyes and face.

Ronix

13 June 2024