- 5min

- 31124

- an opinion

When it comes to heavy-duty projects, pneumatic tools outperform cordless and corded electric tools. They come with sturdy structures and superpowers that are brought about by air compressors.

They are steady powerhouses that supply the energy required for the air tools to perform, perfectly. They are not simple units by the way.

They are made of different parts that together work harmoniously and provide potent strength. If you are interested in these air power units, you will enjoy reading this list of air compressor parts’ names and the descriptions explaining their functions.

Air Compressor Parts’ Name

Here is an air compressor parts list that informs you of the functions and way of performance.

- Pump Mechanism

The pump mechanism is the heart of a compressor that takes the ambient air and increases the pressure through a compression process. Pumps can be of two main types:

- Reciprocating Pump

Reciprocating pumps use pistons that compress air by moving up and down. Based on the number of their pistons, they come in different types including single-stage cylinders and two-stage cylinders.

- Rotary Pump

Rotary pumps compress air through a rotation action. They come in two types of screw and sliding vane pumps.

Order Wholesale Air Compressor Designed to Attract Customers.

The first one uses two intermeshing screws that trap compress air as they rotate, while the second one uses a slotted rotor with vanes that slide in and out of the slots as it rotates within a cylindrical housing.

Drive System

The drive system is the component that supplies the power required to make the pump operate. This system can be in two forms:

- Electric Motor

We can put different types of electric motors on the air compressor parts list. They can be either induction AC motors that are mostly applied, or brushless DC motors that are commonly used in portable compressors.

However, single-phase and three-phase ones are also applicable for air compressors of small and large sizes sequentially.

- Gasoline Engine

Based on the work level, and whether the compressor is heavy-duty or light-duty, its engine can be powered by gasoline, diesel fuel, or natural gas. Gasoline engines are used widely in small-scale air compressors, while diesel engines are commonly found in industrial compressors and the last ones are used when there is no access to gasoline or diesel.

Concerning their placement in the compressor, both types of drive systems I talked about, can be of the following types:

- Direct-coupled

when the motor or engine’s shaft is directly connected to the pump, they are called direct-coupled. They provide a simple and more efficient design for smaller compressors.

- Belt-driven

A belt-driven motor or engine is one in which the shaft is connected to the pump shaft through a belt. It offers flexibility in motor placement and enables the use of larger motors for more powerful compressors.

Valves

Valves are in charge of regulating the flow of air in and out of the pump. There are usually three main valves used on the compressor, including:

- Intake Valve (also called inlet and suction valve) that allows air to enter the pump from outside the too

- Discharge Valve (also called outlet) that opens to release the compressed air into the storage tank.

- Safety Valve that can release pressure if it exceeds a certain limit and prevent the tank from explosion.

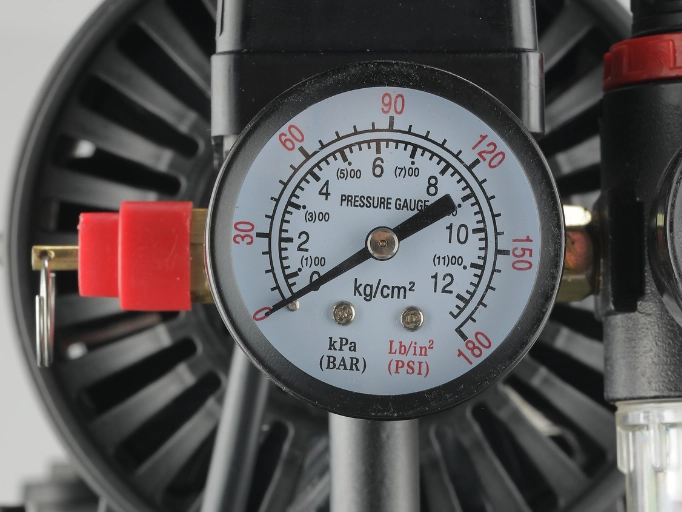

Pressure Gauge

When searching for an air compressor parts name, a pressure gauge is the one that stands out. While it may not directly power the compressor, its role is crucial for ensuring optimal operation. It measures the pressure of the air inside the compressor tank and indicates the pressure level visually, typically in pounds per square inch (PSI) or bar. The data it gives is vital in monitoring and assessing the operation of the air compressor.

Air Tank

The compressor tank or chamber acts as a storage reservoir for compressed air, ensuring a steady supply for various applications. It not only regulates air pressure but also smooths out fluctuations, guaranteeing a consistent flow of compressed air. In essence, the compressor tank is a crucial component in maintaining a reliable and efficient compressed air supply.

Additional Components

Depending on the specific model, the main housing also contains:

- A Lubrication System that reduces friction and wear by lubricating the moving parts of the pump.

- An Air Hose that transfers compressed air to the pneumatic tools.

- A Cooling System that helps to dissipate heat generated during compression, to ensure optimal performance and prevent overheating.

- A Filter which is usually placed near the intake port of the compressor and is in charge of capturing contaminants from the incoming air before it enters the compression chamber.

- Connectors that are used to join various components of the air supply system together, such as hoses, filters, pressure gauges, regulators, and pneumatic tools.

FAQ

What are the basic parts of the air compressor?

The pump mechanism, drive system (including motors or engines), valves, pressure gauge, and air tank are the basic components of an air compressor.

What is the most important part of a compressor?

All the parts are important. But if we want to name one, the pump mechanism is the one we should mention first. Because, it is responsible for compressing air, which is the primary function of the compressor.

Ronix

23 April 2024

very well done simplifying it